|

Bogenoffset |

|

|

|

|

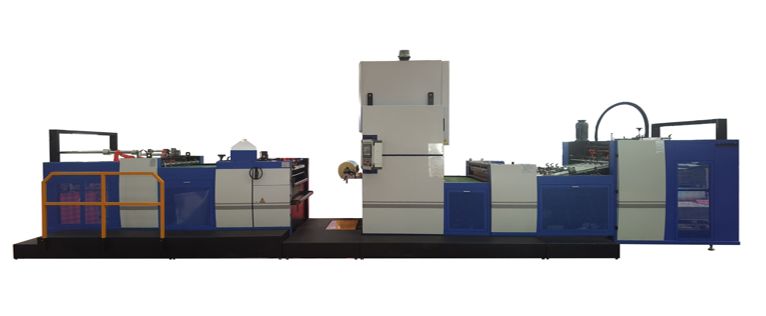

Heidelberg, MOZ-S, 1992 (Ref.:M6606)

Baujahr: 1992 Format: 480 x 650 mm Druckzahl: 42 Mio

Preis: auf Anfrage

Alcolor Dampening

CP Tronic

Stream feeder

machine is in good condition without damages

All tools and manuals |

|

|

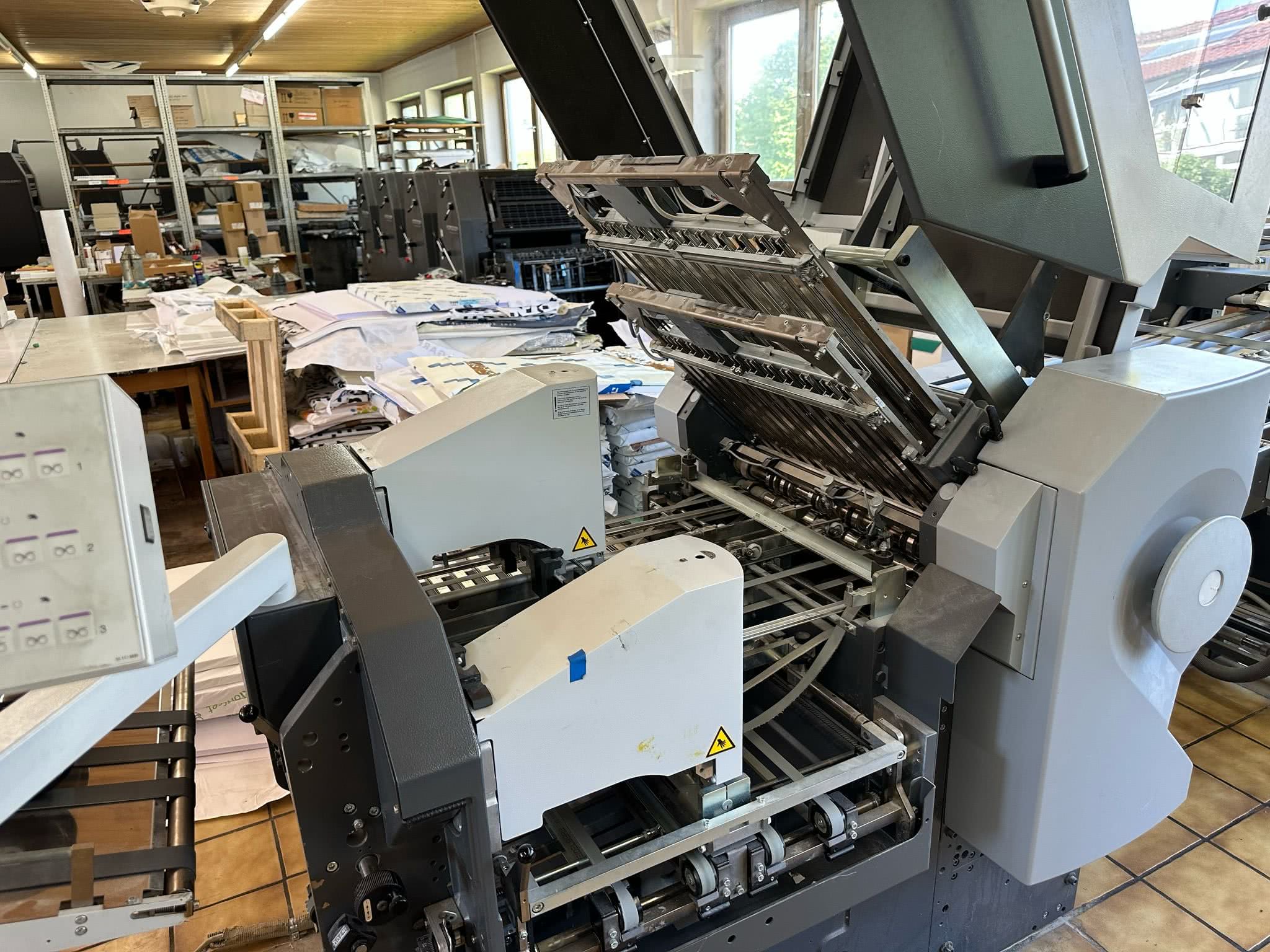

Heidelberg, Speedmaster CD 74-5+L, 2004 (Ref.:M6647)

Baujahr: 2004 Format: 530mm x 740mm (C-Format)

Preis: auf Anfrage

Prinect CP2000 Center mit Farbfernsteuerung

Preset Anleger

Alcolor Vario-Filmfeuchtwerk

Feuchtmittelzentrale HydroStar

Programmgesteuerte Farbwalzenwascheinrichtung

Autoplate

Programmgesteuerte Gummituchwascheinrichtung

AirTransfer, luftunterstützte Bogenführung zwischen den Druckwerken

Preset Hochstapelausleger mit Trocknereinschubmöglichkeit

Zentraler Luftversorungsschrank AirStar

Zweiwalzen-Lackiersystem

fernverstellbares Seiten-, Umfang- und D

verlängerter Ausleger (160cm) mit 3 Troc

Dry Star LYL für Zwischenstationen bei D

Breite 3,31m |

|

|

KBA, RAPIDA 162A 6+lak PWVA ALV3, 2001 (Ref.:M6398)

Baujahr: 2001 Format: 1200 x 1620 mm Druckzahl: 258 mio

Preis: auf Anfrage

halbautomatischer Plattenwechsel.

Non-Stop-Zuführung und -Auslieferung

Remote Ergotronic mit Colortronic-Konsole

Umfangs- und Diagonalregister-Fernsteuerung

Hybrid – konventionelle oder Hybrid-Tinten

Ultraschall-Doppelbogendetektor

Varidamp-Alkohol-Feuchtmittelsystem

Baldwin-Kühlung und -Umwälzung |

|

|

|

Weiterverarbeitung |

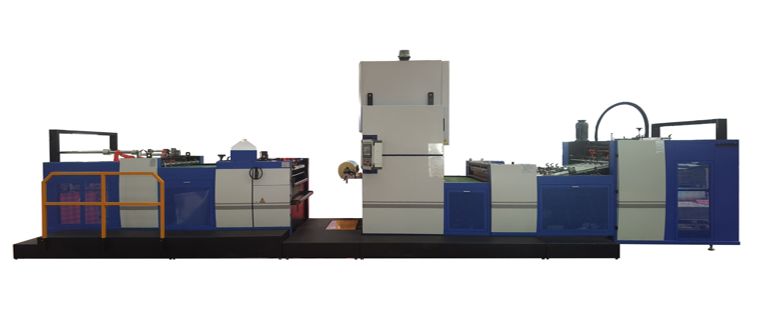

KMK Printing & Packaging Machinery, KMK-1100 GS, 2024 (Ref.:M5583)

Baujahr: 2024 Format: 1100 mm

Preis: auf Anfrage

max. Kartondicke. 800 gsm

Wellpappen typen: N, E, F

Geschwindigkeit 400 m / min.

max.Tippbetrieb 10 m / min.

max. Dicke der gefalteten Box 20 mm

max. Einlaufbreite 1100 mm

Maße 15 x 1,70 x 1,90 m

Nettogewicht 7,6 T

benötigte Elektrizität 15 kW

benötigte Druckluft 6 bar

Druckluft Kapazität

https://www.youtube.com/watch?v=9G5QLOqK |

|

|

Josef Foellmer, IRAM 400/4, 1991 (Ref.:M6188)

Baujahr: 1991 Format: 98 x 60 cm

Preis: auf Anfrage

- **Bohrdurchmesser**: 3-10 mm (optional bis 22 mm)

- **Bohrtiefe**: Max. 70 mm

- **Spindelabstand**: Verstellbar von 45 mm bis 540 mm

- **Lochabstand**: Min. 3 mm, Max. 800 mm

- **Tischgröße**: 98 x 60 cm

- **Zusätzliche Funktionen**: Bohrlängenkompensation, Kühlung/Schmierung, Geschwindigkeitsregelung |

|

|

|

|

KMK Printing & Packaging Machinery, KMK PCS 1200, 2024 (Ref.:M6347)

Baujahr: 2024

Preis: auf Anfrage

Papiermaterial: Karton 210-800 g/m², A/B/E A/B/E-Welle

Max. Geschwindigkeit: 260 m/min

Max. Dicke der Faltschachtel: 12 mm

Faltart: 180° Falte 2 und Falte 4 sind 180°

Stromversorgung: 3P 380V 50HZ

Rohlingsbreite: 1200 mm

Länge x Breite x Höhe: 14 x 1,9 x 1,7 m

Nettogewicht: 6,5 t

Gesamtleistung: 20 kW

Gerader Kasten: Typ Modell 1200

Faltart: Drei Träger

B+C+D+E: 280-1200

C+D: 140

E (Min): 30 |

|

|

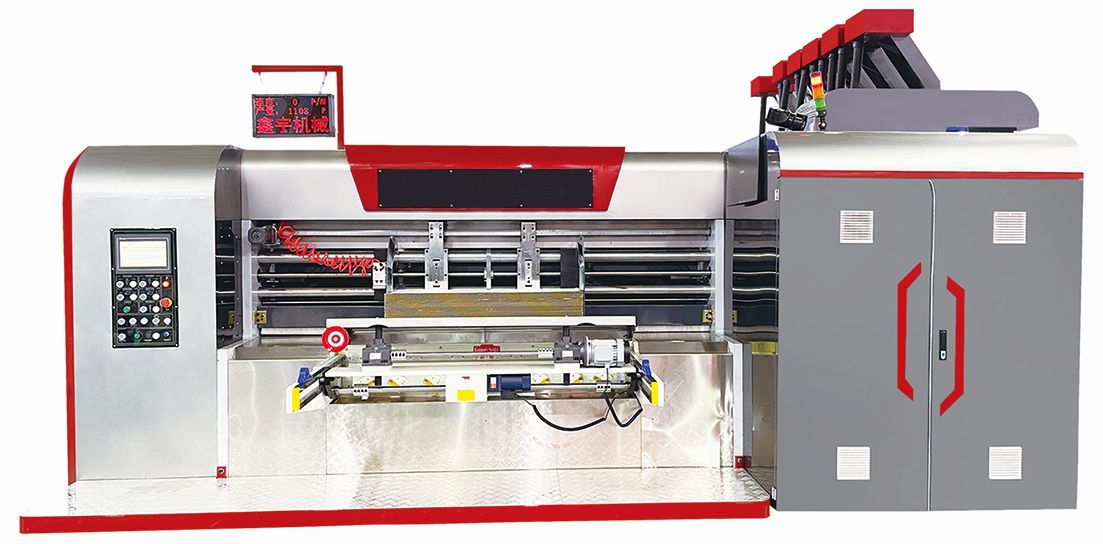

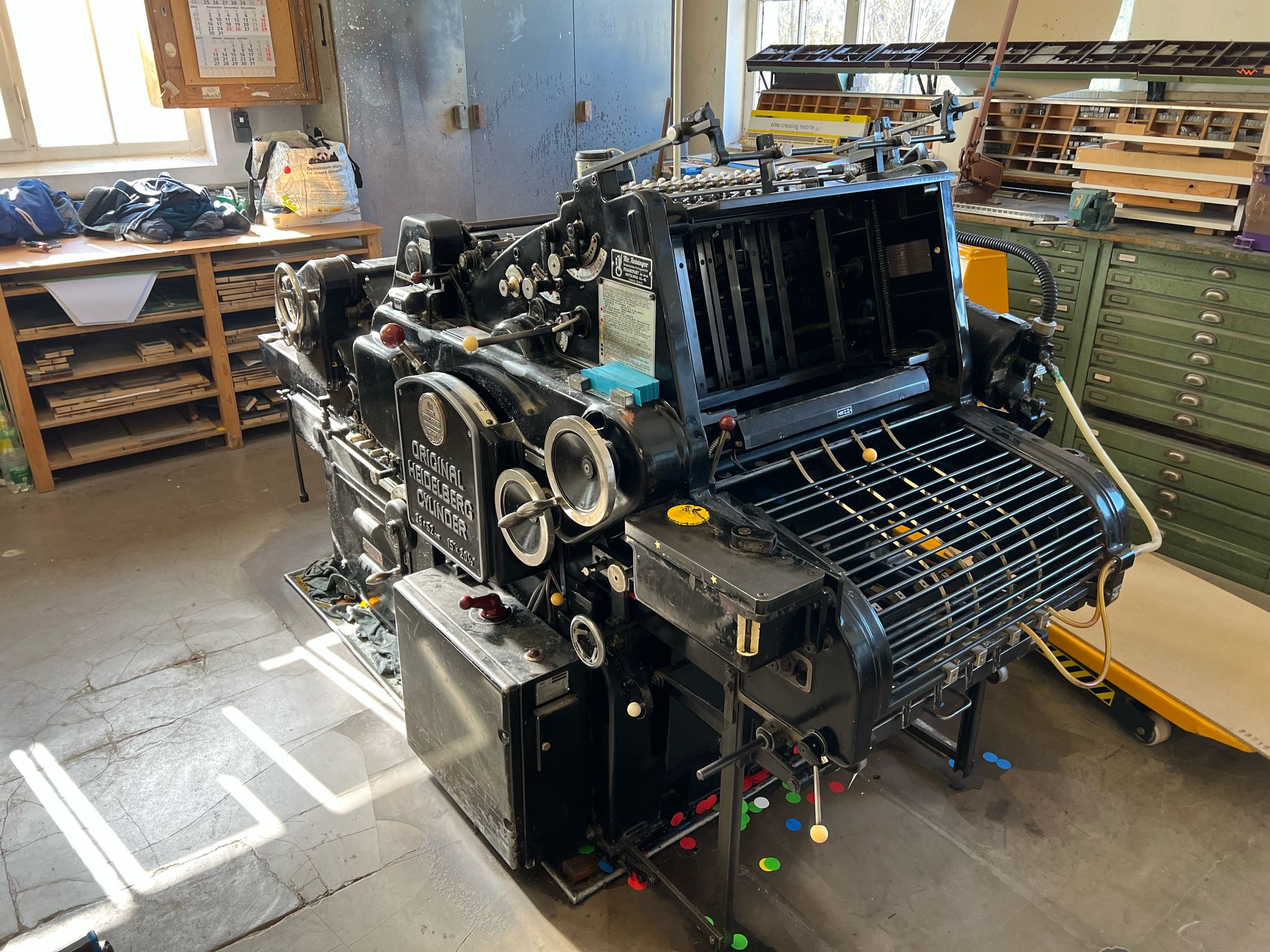

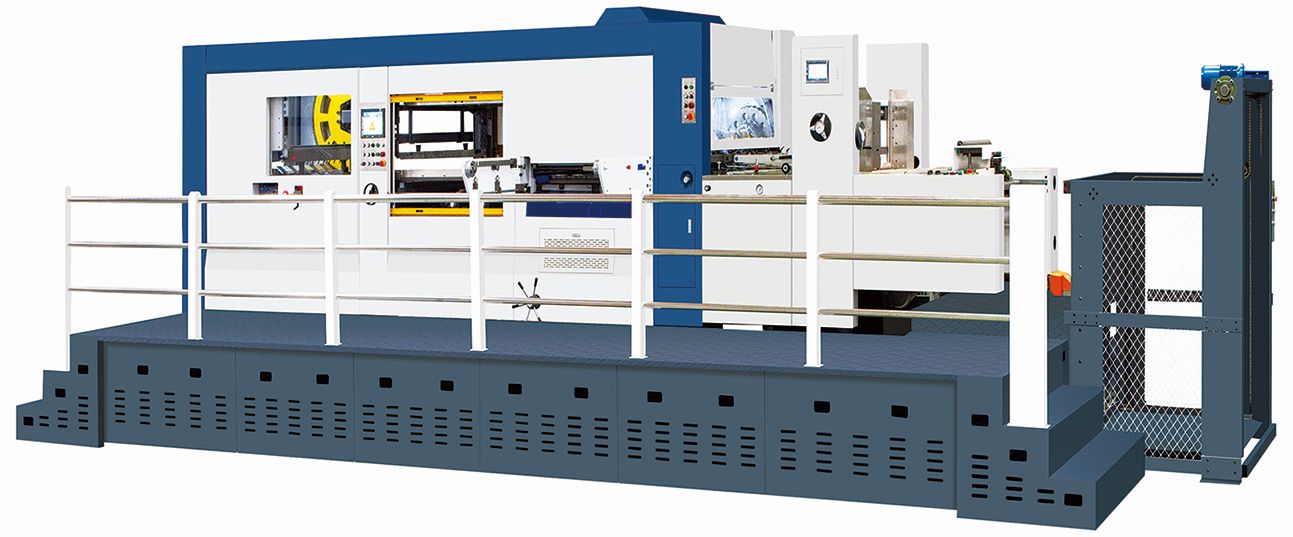

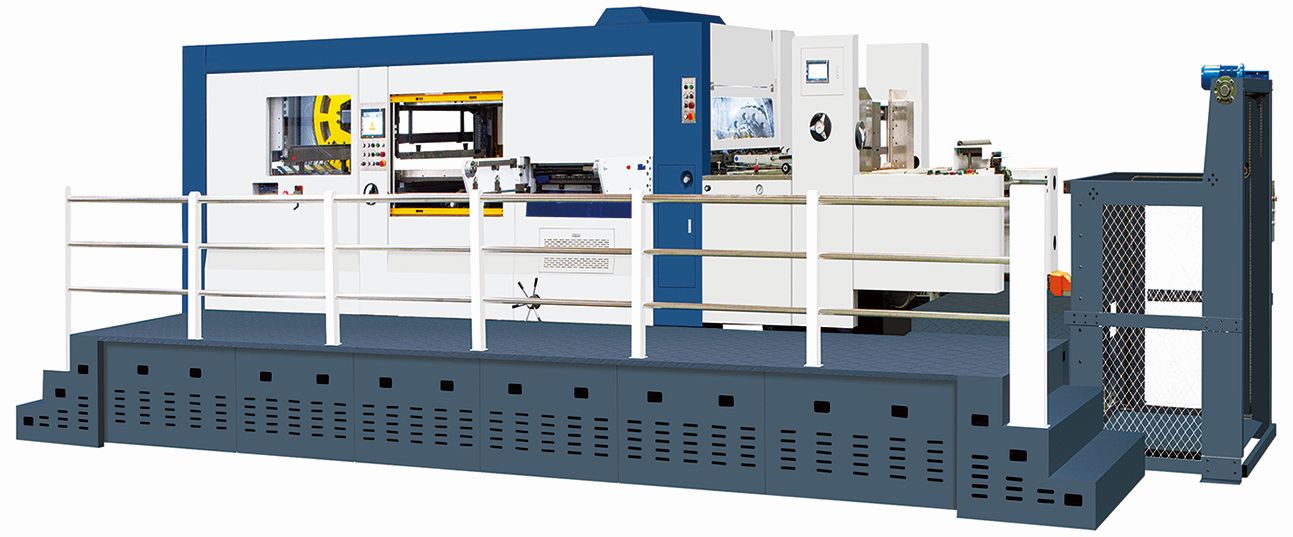

KMK Printing & Packaging Machinery, KMK 106-MTF, 2024 (Ref.:M5586)

Baujahr: 2024 Format: 1060 x 770 mm

Preis: auf Anfrage

Max. Format: 1060 x 770 mm

Min. Format: 450 x 370 mm

Max. Stanzformat: 1050 × 750 mm

Max. Prägeformat: 1050 × 750 mm

Greifer Marge: 8 - 17 mm

Papiergewichte: 90 - 2000 g/m2 (Karton) 0.1 - 2mm (Karton) ? 4 mm (Wellpappe)

Max. Stanzkraft: 300 T

Max. Geschwindigkeit: 7500 Bögen/Stunde

Max. Prägegeschwindigkeit: 6500 Bögen/St

Individuell beheizte Zonen: 12 beheizte

werden bis max. 200 grad)

Max. Folienlängsdurchmesser: 250 mm |

|

|

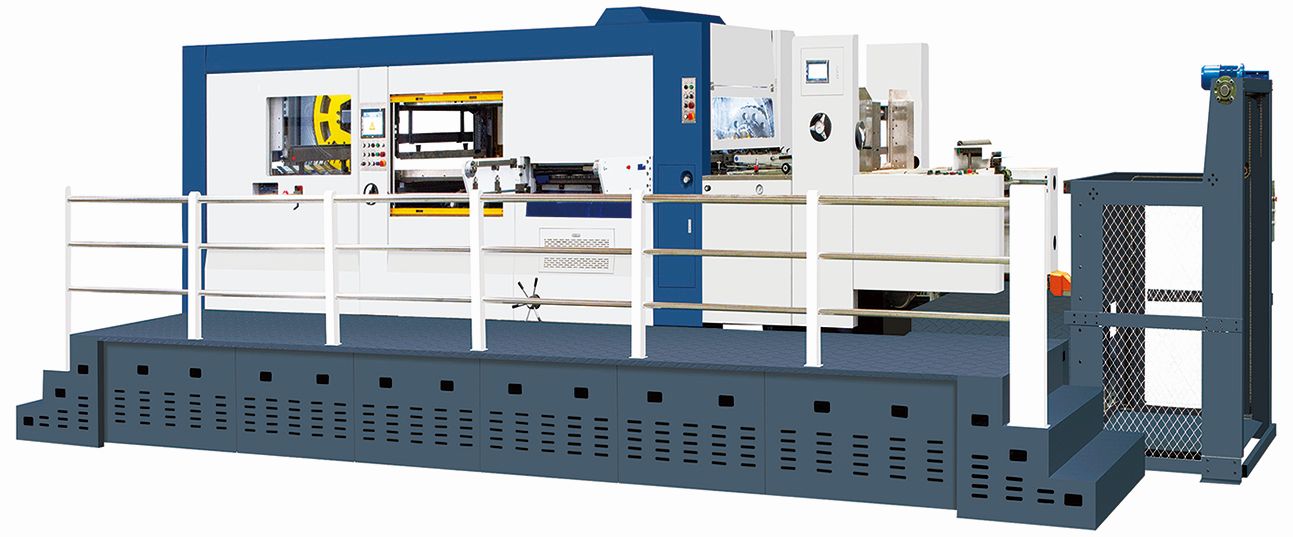

KMK Printing & Packaging Machinery, KMK C-150, 2024 (Ref.:M6032)

Baujahr: 2024 Format: 1510 × 1120 mm

Preis: auf Anfrage

Stanzstil: Flachbettstanze

Max. Stanzgröße: 1500 × 1100 mm

Max. Stanzdruck: 350 T

Papierverarbeiteter Karton: 1-8 mm

Max. Stanzgeschwindigkeit: 4500 Blatt / h

Max. Stapelhöhe Anleger: 500 mm

Max. Stapelhöhe Auslage: 330 mm

Hauptmotorleistung: 15 kW

Gesamtleistung: 38 kW

Gewicht: 26 T

Abmessungen: 11470 x 5000 x 2600 mm

Inklusive Ausbrechstation |

|

|

KMK Printing & Packaging Machinery, KMK-1050, 2024 (Ref.:M5587)

Baujahr: 2024 Format: 560 x 350 mm

Preis: auf Anfrage

max. Format 1050 x 750 mm

min. Format 560 x 350 mm

Geschwindigkeit 800- 4.000 Stück/ Std.

max.Druckfläche 1050 x 740 mm

Siebdruckrahmen 1300 x 1170 mm

Paperdicke 90-420 gramm

Maße 4750 x 3060 x 1720 mm

https://www.youtube.com/watch?v=KuecXf-ZxjA |

|

|

KMK Printing & Packaging Machinery, KMK 72-UV, 2024 (Ref.:M5607)

Baujahr: 2024 Format: 250 x 300 mm

Preis: auf Anfrage

mit TC -800 UV Trockner

mit TC 800 S automatischem Abstapler

max. Format: 520 x 720 mm

min. Format: 250 x 300 mm

Rahmen Format: 900 x 920 mm

Druckgeschwindigkeit: 400-2400 / Std.

Energiebedarf 3 P 380 V 50 Hz 7W

Gewicht: 3550 KG

Abmessungen 3250 x 2550 x 2080 |

|

|

KMK Printing & Packaging Machinery, KMK-1050, 2025 (Ref.:M6095)

Baujahr: 2025 Format: 1050 x 750 mm

Preis: auf Anfrage

max. Format 1050 x 750 mm

min. Format 560 x 350 mm

Geschwindigkeit 800- 4.000 Stück/ Std.

max.Druckfläche 1050 x 740 mm

Siebdruckrahmen 1300 x 1170 mm

Paperdicke 90-420 gramm

Maße 4750 x 3060 x 1720 mm

Video in Produktion: https://www.youtube.com/watch?v=Ww7rlEZjqo8 |

|

|

|

|

KMK Printing & Packaging Machinery, KMK LK 106-M, 2024 (Ref.:M6035)

Baujahr: 2024 Format: 400 x 370 mm

Preis: auf Anfrage

Max. Format: 1060 x 770 mm

Min. Format: 400 x 370 mm

Max. Stanzformat: 1050 × 750 mm

Greifer Marge: 8 - 17 mm

Papiergewichte: 90 - 2000 g/m2 (Karton) 0.1 - 2mm (Karton) <_ 4 mm (Wellpappe)

Max. Stanzkraft: 300 T

Max. Geschwindigkeit: 7500 Bögen/Stunde

Max. Stapelhöhe Auslage: 1200 mm

Max. Stapelhöhe Anleger: 1350 mm

Hauptmotorleistung: 11 kW

Maschinenleistung

: 17.6 kW |

|

|

KMK, AEM-800Q, 2024 (Ref.:M6269)

Baujahr: 2024 Format: 800×620 mm

Preis: auf Anfrage

Technische Daten:

Max. Blattgröße 800×620 mm

Mindest. Blattgröße 340×280 mm

Futterstapelhöhe 1150 mm

Lieferstapelhöhe 1000 mm

Max. Stanzgröße 770×600 mm

Innere Chase-Größe 820×628 mm

Stanzplattengröße 826×628 mm

Schnittmaßhöhe 23,8 mm

Schneidplattenstärke 7 mm

Lagersortiment:

Pappe: 0,1 bis 2 mm

Wellpappe: <4 mm |

|

|

KMK, AEM-800, New 2025 (Ref.:M6594)

Format: 800×620 mm

Preis: auf Anfrage

Technische Daten:

Max. Blattgröße 800×620 mm

Mindest. Blattgröße 340×280 mm

Futterstapelhöhe 1150 mm

Lieferstapelhöhe 1000 mm

Max. Stanzgröße 770×600 mm

Innere Chase-Größe 820×628 mm

Stanzplattengröße 826×628 mm

Schnittmaßhöhe 23,8 mm

Schneidplattenstärke 7 mm

Lagersortiment:

Pappe: 0,1 bis 2 mm

Wellpappe: <4 mm |

|

|

|

|

KMK, KMK-580B, 2017 (Ref.:M6444)

Baujahr: 2017 Format: 580 x 740 mm Druckzahl: 1000 h worked

Preis: auf Anfrage

max. Bogenformat 580 x 740 mm

min. Bogenformat 210 x 210 mm

Materialdicke 105 - 500 gramm

Geschwindigkeit 30 - 50 m / min.

Maße 3660 x 1278 x 1780 mm |

|

|

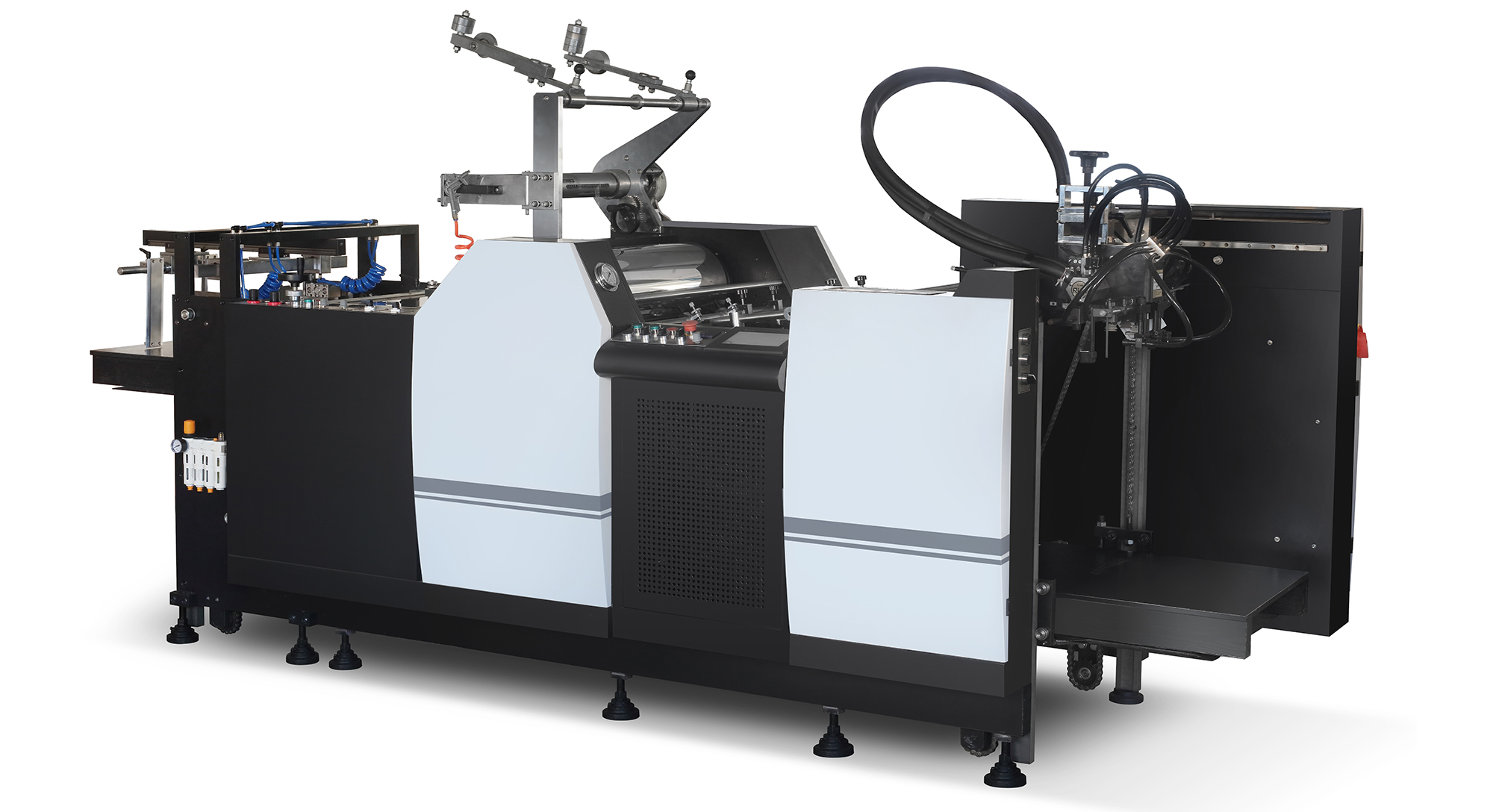

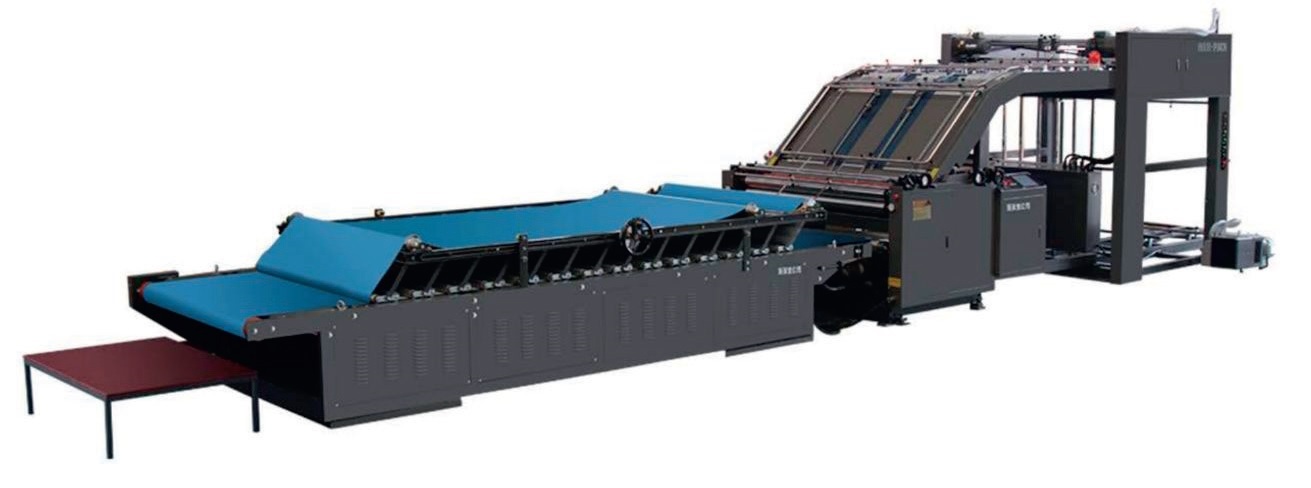

KMK Printing and Packaging Machinery, KPZ1300 UV Varnishing, 2024 (Ref.:M6453)

Baujahr: 2024 Format: 1280 x 1650 mm

Preis: auf Anfrage

Max. Beschichtungsbreite: 1300 mm

Max. Bogenformat: B1280 mm x L1650 mm

Min. Bogenformat: B320 mm x L400 mm

Höhe des Stapels am Anleger/Ausleger: 1360/1300 mm

Bogendicke: 80-500 g/m²

Max. Arbeitsgeschwindigkeit: 100 m/min oder 7000 Bogen/h

Installierte Leistung: 76 kW

Gesamtgewicht: 8600 kg

Abmessungen: 14,1 × 2,2 × 2,2 m

1. Automatischer Einleger:

Die Geschwindigkeit des Papiereinlege

Transport des Papiereinlegers kann vorwä

kleiner Papierformate erleichtert. Vier

Papiergeradheit kann bis zu ±2 mm erreic |

|

|

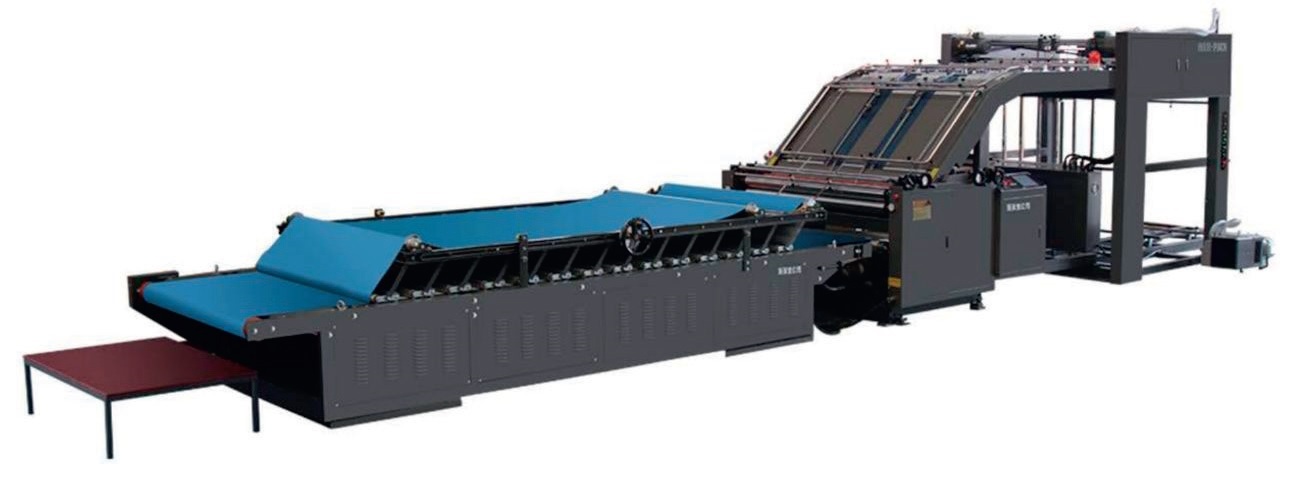

KMK Printing and Packaging, KPZ1100 UV Varnishing, 2024 (Ref.:M6422)

Baujahr: 2024 Format: 1080x1200 mm

Preis: auf Anfrage

Minimal 320x290 mm

Papier Dicke 80-500gsm

Auslage Höhe 1300 mm

Maximale Geschwindigkeit 100 m/min.

Gewicht 7500kg

Energieverbrauch 65 kW

LxBxH 12.5x2x2m

Maximal 1080x1200 mm

1. Automatischer Einleger:

Die Geschwindigkeit des Papiereinlege

Transport des Papiereinlegers kann vorwä

kleiner Papierformate erleichtert. Vier

Papiergeradheit kann bis zu ±2 mm erreic |

|

|

KMK Printing & Packaging Machinery, KMK S-450, 2024 (Ref.:M6360)

Baujahr: 2024

Preis: auf Anfrage

Die größte Box: 450 x 200 mm

Maschinenabmessungen: 2100x2000mm

Gewicht: 500 kg

Spannung: 220V/50Hz

Leistung: 1,2 kW

+ Zugehöriges Zubehör:

Vorspeisegerät

Sprühsystem: Ausgestattet mit drei Pistolen, praktisch für die Herstellung von 4/6-Eckschachteln und

verschiedenen speziell geformten Schach

Plasmaprozessor: Durch Oberflächenbeschi

Kartons zu erleichtern. |

|

|

MKS Sysform, BM-20, 2016 (Ref.:M5537)

Baujahr: 2016

Preis: auf Anfrage

max. Faltkapazität: 20 Bögen (70 gramm)

max. Papierlänge: 330 mm x 480 mm A3+

min. Papierlänge: 182 mm x 257 mm

geschwindigkeit: 1800 Stück/Std. |

|

|

MWT, Octoplus US 3000, 2010 (Ref.:M6485)

Baujahr: 2010 Format: 50 x 35 cm

Preis: auf Anfrage

MWT OCTOPLUS US 3000 – Hochleistungs-Broschürenfertigungssystem

Die MWT OCTOPLUS US 3000 ist eine fortschrittliche Weiterverarbeitungsmaschine, die für eine

effiziente und hochwertige Broschürenproduktion entwickelt wurde. Durch ihre robuste Bauweise und

präzise Verarbeitung sorgt sie für eine zuverlässige und reibungslose Produktion von

Druckerzeugnissen.

Funktionen und Eigenschaften:

- Heftaggregat – Sorgt für eine präzise Drahtheftung von Broschüren in verschiedenen Formaten.

- Falzaggregat – Ermöglicht eine exakte Falzung für eine perfekte Endverarbeitung.

- Frontschnittaggregat – Führt einen präzisen Beschnitt für saubere Kanten und eine professionelle

Optik durch.

- Hochgeschwindigkeitsverarbeitung – Opt

Stillstandszeiten.

- Modulares Design – Ermöglicht einfache

Produktionslinien.

- Benutzerfreundliches Interface – Einfa |

|

|

Palamides, Delta 705, (Ref.:M6628)

Format: 760 x 305mm

Preis: auf Anfrage

Arbeitsbreite 700 mm mit 5fach Banderolierung

Formatbereich max. 760 x 305mm, min. 110 x 95 mm

Bandbreite 30 mm

automatische Formaterkennung und Makulaturbogen-Erkennung

Pressstation mit Vor- und Hauptpressung, mit Hauptpresswalze

Paket Pressung

Rüttelstation

autom. Formateinstellung

Grossformatauslage

Verschiedene Bedienungsmodi, Schuppe

Stangenbündelung

Leistung 600 Pakete pro Stunde

Pakethöhe: min. 20 mm

Pakethöhe: max. 150 mm |

|

|

Sure, Paper Drill 25, (Ref.:M6154)

Format: 50 mm

Preis: auf Anfrage

- Modell: Sure Paper Drill 25

- Bohrtyp: Papierbohrmaschine mit 2 Spindeln

- Bohrabstand: Verstellbar zwischen den Spindeln

- Max. Bohrdurchmesser: 10 mm

- Max. Stapelhöhe: 50 mm

- Max. Bohrtiefe: 60 mm (einstellbar)

- Bohrtiefe: Fein einstellbar über Anschlag

- Papieranschläge: Vorne und seitlich justierbar

- Tisch: Stabil und höhenverstellbar

- Bohrhub: Manuell über Handhebel

- Bohrgeschwindigkeit: Konstant

- Stromanschluss: 230 V / 50 Hz

- Maße (ca.): 60 × 50 × 80 cm (L×B×H)

- Gewicht: ca. 50 kg

- Zustand: Gebraucht, voll funktionsfähi |

|

|

|

|

|

|

Kolbus, HD140 P, 1996 (Ref.:M6505)

Baujahr: 1996 Format: 305x420x80mm

Preis: auf Anfrage

Technische Daten – Kolbus HD 140 P

- Co-Pilot-System für automatischen Formatwechsel in nur 7 Minuten

- Max. Format: 305 x 420 mm

- Beschnittenes Format:

- Max.: 300 x 400 mm

- Min.: 100 x 100 mm

- Buchblockdicke:

- Max.: 80 mm

- Min.: 2 mm

- Einzugshöhe: 80 mm

- Geschwindigkeit: max. 3.900 Takte/Stun

- Maschinenlänge: 2.400 mm

- Maschinenbreite: 3.060 mm

- Maschinenhöhe: 1.740 mm |

|

|

Polar, TR 1 ER 145-3, 1991 (Ref.:M6514)

Baujahr: 1991 Format: 145 x 105

Preis: auf Anfrage

Polar TR 1 ER 145-3 – Transformator / Entlader

- Serien Nr. 6191311

- Stückzahl: 1

- Hersteller: Polar

- Typ: TR 1 ER 145-3

- Einsatzbereich: Automatisches Entladen von geschnittenem Material

- Entladehöhe einstellbar

- Stapelbildung auf Palette

- Sanfter Materialtransport durch Hub- und Schwenkbewegung

- Robuste Industrieausführung für Dauerbetrieb

- Platzsparende Bauweise |

|

|

Shoei Star, Little Mach, 1993 (Ref.:M6411)

Baujahr: 1993 Format: 50cm

Preis: auf Anfrage

- Max. Papierformat: 470 x 650 mm

- Min. Papierformat: 120 x 135 mm

- Max. Papiergewicht: 250 g/m²

- Min. Papiergewicht: 40 g/m²

- Arbeitsbreite: Bis zu 50 cm

- Vakuum-Saugzuführung

- Flachstapelzuführung

- Geräuschschutzhaube

- Digitales Bedienfeld mit Programmen

- Zwei Taschen zum Falzen

- Zähler für Bogen

- Optionale Zusatzausstattung: Rill- und

- Geschwindigkeit: Bis zu 40.000 Bogen p

- Stromversorgung: 380 V, 50/60 Hz |

|

|

|

|

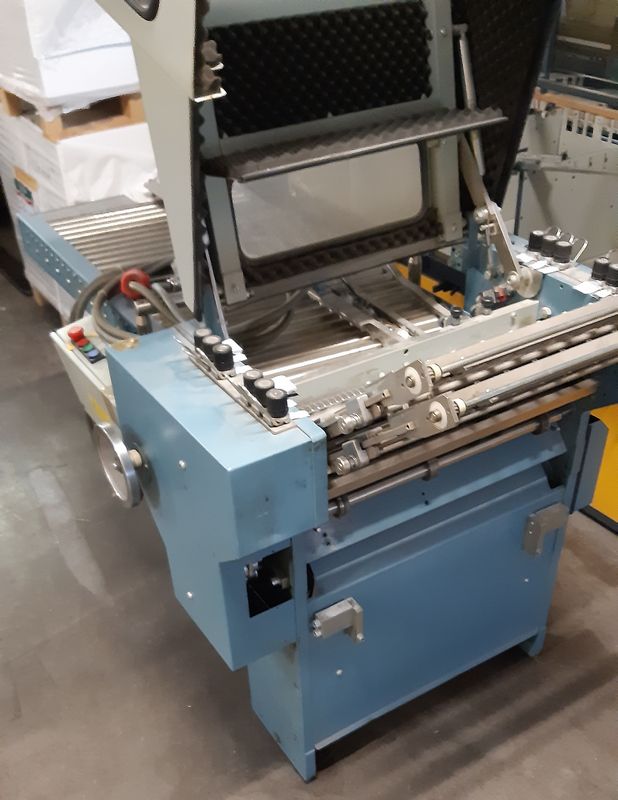

Heidelberg, TI 52/6-4-2-R, 2003 (Ref.:M6510)

Baujahr: 2003 Format: 520 x 840 mm

Preis: auf Anfrage

- Falzstationen: 1. Falzwerk mit 6 Taschen (Parallelfalz)

- Falzstationen: 2. Falzwerk mit 4 Taschen (Parallelfalz)

- Falzstationen: 3. Falzwerk mit 2 Taschen (Parallelfalz)

- Max. Bogenformat: 520 x 840 mm

- Min. Bogenformat: 105 x 148 mm

- Max. Geschwindigkeit: bis zu 30.000 Bogen/Stunde (abhängig vom Falzschema und Material)

- Papiergewicht: 40 – 250 g/m²

- Falzarten: Einfachfalz, Wickelfalz, Zickzackfalz, Doppelparallelfalz u.v.m.

- Anleger: Flachstapelanleger (PBA)

- Steuerung: Elektronische Steuerung mit Falzprogrammspeicher

- Auslage: Schuppenauslage (STA)

- Optional: Perforier-, Rill- oder Schne

- Formatverstellung: Manuell

- Maschinenmaße (L x B x H): ca. 2.800 x

- Gewicht: ca. 1.000 – 1.200 kg |

|

|

Heidelberg Stahl Folder, CH-56-4-KT-FFH, 2015 (Ref.:M6539)

Baujahr: 2015 Format: 560 x 900 mm

Preis: auf Anfrage

16-Seiten vollautomatische, einstellbare Kombifalzmaschine

Flachstapelanleger mit Tremat und MCT mit Touchdisplay

4x Falztaschen Automatische Rollen- und Tascheneinstellung

KT Kreuzfalzwerk mit 2 Falzmessern

1 liegende Faltschnalle nach 1. Faltmesser

Kompressor (Pumpe)

Anti-Lärm-Haube

mobile Bandauslage SAK 56 mit MCT

Technische Daten:

Min. Format: Format min. 140×180 mm

Max. Format: Format max. 560×900 mm

Min. Stärke: Paper weight (g/m²) 40 – |

|

|

Stahl, Ti 40/4-SAK, 2006 (Ref.:M6540)

Baujahr: 2006 Format: 400 x 650 mm

Preis: auf Anfrage

Zuführung

Feeder-Modus: Flachstapel-Feeder

Typ: FI-40

Steuergerät: DCT 500

Falzeinheiten

1. Einheit

Typ: Ti-40

Jahr: 2004

Taschen: 4

Taschentyp: Kombi-Faltplatten

Taschenkonfiguration: manuell

Rollenkonfiguration: manuell

Walzenzustand: gebrauchter Zustand

Lärmschutzhaube

Seriennummer: FH.FANF-00226 |

|

|

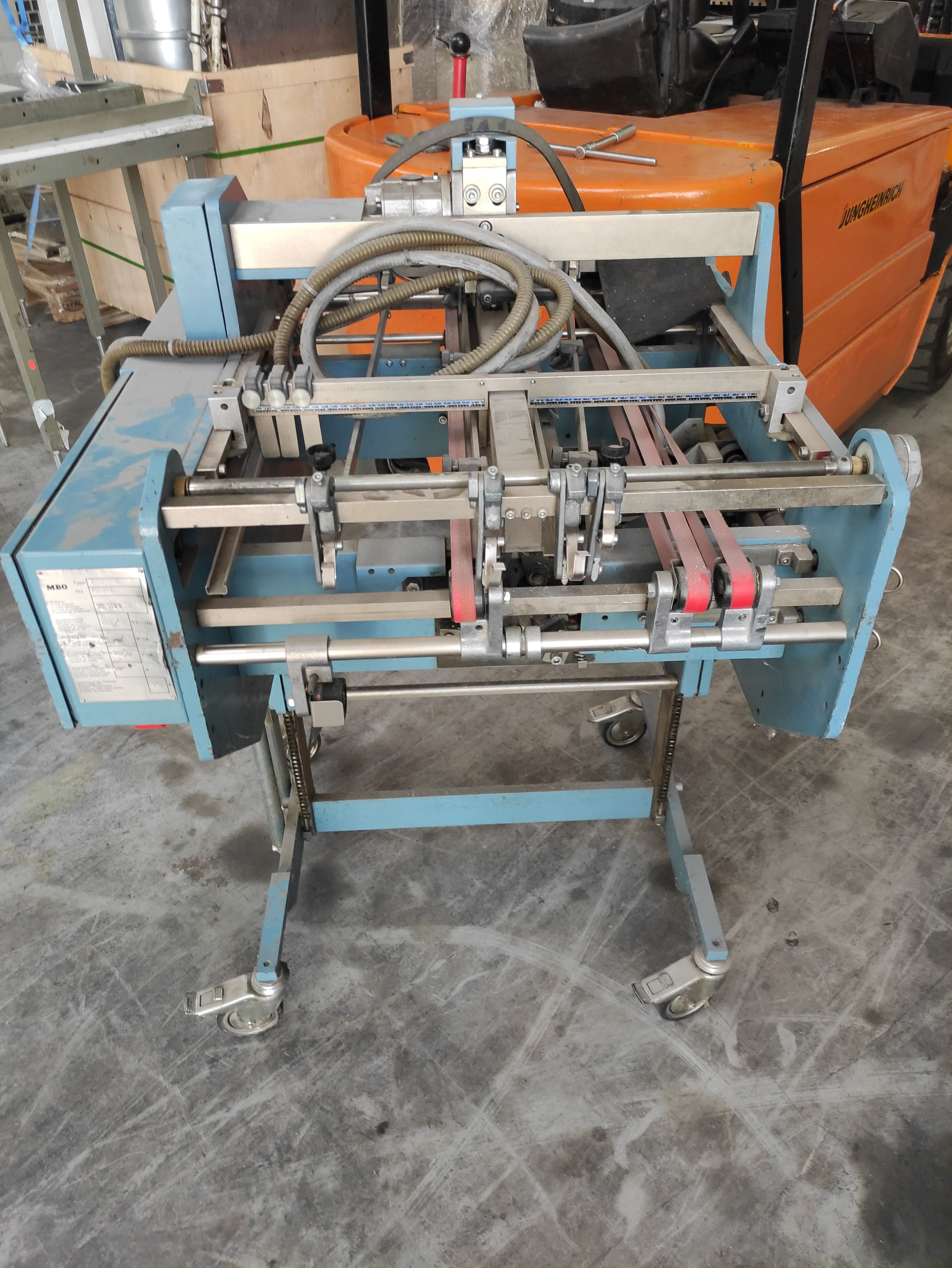

MBO, M 80/4 KL, 2013 (Ref.:M6574)

Baujahr: 2013 Format: 830 x 1240 mm

Preis: auf Anfrage

Counter : 550.000

- 4 Pockets

- 2 Knifes

- Roundpile feeder

- Antinoise Hoods

- M1 Advanced inkl. Touchscreen

- Manual Roller Setting

- MWK |

|

|

MBO, K 800.2 S-KTL/6, 2009 (Ref.:M6625)

Baujahr: 2009 Format: 780 x 1.200 mm

Preis: auf Anfrage

6 Taschen

Steuergerät: Navigator-Control mit Touchscreen

Falteinheiten

1. Einheit

Taschen: 6x

Kreuzfalteinheit mit 2x Messer

Zweites Messer ausgerichtet auf: Links

1x Seitentasche

Geräuschschutzhaube

mit Palamides Alpha 700, Baujahr: 2007, |

|

|

MBO, K 800.2 S-KTL/ T6, 2001 (Ref.:M6630)

Baujahr: 2001 Format: 780 x 1.200 mm

Preis: auf Anfrage

- Hersteller: MBO

- Modell: K 800.2 S-KTL/6

- Maschinentyp: Falzmaschine (Kombifalzmaschine)

- Formatbreite: 78–80 cm (Baureihe 800)

- Typische Anwendung: Hochleistungsfalz im mittleren bis großen Formatbereich

- Merkmale: 6 Falztaschen, KTL-Ausführung (Kombination aus Taschen- und Schwertfalz), hohe

Produktivität, präzise Falzungen

- Einsatzgebiet: Industrielle Druckereien, Weiterverarbeitungsbetriebe |

|

|

MBO, K820-4KTLT, 1996 (Ref.:M6631)

Baujahr: 1996 Format: 820 mm

Preis: auf Anfrage

- Hersteller: MBO

- Modell: K 820-4KTLT

- Maschinentyp: Falzmaschine (Kombifalzmaschine)

- Formatbreite: 82 cm

- Typische Anwendung: Hochleistungsfalz für große Druckbogenformate

- Merkmale: 4 Falztaschen, KTLT-Ausführung (Kombination aus Taschen-, Schwert- und Querfalz), hohe

Produktionsgeschwindigkeit, präzise Falzungen

- Einsatzgebiet: Industrielle Druckereien, Weiterverarbeitungsbetriebe mit Großformatproduktion |

|

|

Nagel, Docufold, 2004 (Ref.:M6071)

Baujahr: 2004 Format: 674 x 365 mm

Preis: auf Anfrage

- **Maximale Papiergröße**: 674 mm x 365 mm

- **Minimale Papiergröße**: 140 mm x 148 mm

- **Maximales Papiergewicht**: 240 g/m² (variiert je nach Material)

- **Minimales Papiergewicht**: 60 g/m²

- **Geschwindigkeit**: Bis zu 27.000 A4-Bögen pro Stunde (je nach Material und Faltung)

- **Ladekapazität**: Bis zu 500 Blatt

- **Elektrische Anforderungen**: 240V, 50/60 Hz

- **Abmessungen**: 1240 mm x 555 mm x 1360 mm

- **Gewicht**: 118 kg |

|

|

|

|

|

|

MBO, K 80 S-KTL/4, 2017 (Ref.:M6598)

Baujahr: 2017 Format: 780 x 1.200 mm

Preis: auf Anfrage

## MBO K80/4 SKTL Rundstapelanlage (2017)

### Technische Daten

- Modell: MBO K80/4 SKTL

- Baujahr: 2017

- Falzstationen: 4 Taschen (Parallelfalz)

- Max. Bogenformat: ca. 780 x 1.200 mm

- Min. Bogenformat: ca. 150 x 200 mm

- Papiergrammaturen: 50 – 250 g/m²

- Stapelanleger: Rundstapelanleger für kontinuierliche Zuführung

- Geschwindigkeit: bis zu 230 m/min

mit Palamides Alpha 700 plus,F-123-09, B |

|

|

MBO, T800, 2008 (Ref.:M6599)

Baujahr: 2008 Format: 780 x 1.200 mm

Preis: auf Anfrage

T 800.1-1 78/6 6 x Taschen

T 800.1-2 68/4 4 x Taschen

T 800.1-3 56/2 2 x Taschen

Palamides Alpha 700 Plus, F-123-09, Baujahr: 2010 Auslage |

|

|

|

|

|

|

|

|

Stahl, TI 52, 2004 (Ref.:M6629)

Baujahr: 2004 Format: 52cm

Preis: auf Anfrage

- Hersteller: Stahl

- Modell: TI 52

- Maschinentyp: Falzmaschine

- Formatbreite: 52 cm

- Typische Anwendung: Falzen von Druckbögen im Klein- bis Mittelformat

- Merkmale: robust, vielseitig einsetzbar, kompakte Bauweise

- Einsatzgebiet: Akzidenzdruckereien, Buchbindereien |

|

|

Stahl, KD 78, 2000 (Ref.:M6633)

Baujahr: 2000 Format: 78cm

Preis: auf Anfrage

- Hersteller: Stahl / Heidelberger

- Modell: KD 78

- Maschinentyp: Falzmaschine (Kombifalzmaschine)

- Seriennummer: 701685/00-284045

- Formatbreite: 78 cm

- Baujahr: n/a

- Ausstattung:

• Palettenanleger, Heidelberger Typ PD-78-T, SN 701685/00-284045

• Falzmaschine, Heidelberger Typ KD2-78/4, SN 701685/00-284045

• Falzwerk, Heidelberger Typ 2TD-66/6-T, SN 701685/00-284045

• Auslage (Rundauslage), Heidelberger

• 5 Stahlschränke, verschiedene Ausfüh

• Zubehör: diverse Maschinenzubehörtei

- Einsatzgebiet: Druckereien, Weitervera |

|

|

Stahl, TD 78 4/6, 1998 (Ref.:M6634)

Baujahr: 1998 Format: 78cm

Preis: auf Anfrage

- Hersteller: Stahl

- Modell: TD 78/4-6 (Civiemme)

- Maschinentyp: Taschenfalzmaschine

- Seriennummer: 108526/98-263041

- Formatbreite: 78 cm

- Ausstattung:

• Palettenanleger, Typ PD78-T, SN 108526/98-263041

• Falzmaschine, Stahl Typ TD78/4, SN 108526/98-263041

• Falzwerk, Stahl Typ 2.TD66/6-T, SN 108526/98-263041

• Bündelstation, Civiemme

• 2 Stahlschränke, verschiedene Ausfüh

• Zubehör: diverse Maschinenzubehörtei

- Einsatzgebiet: Druckereien, Weitervera |

|

|

MBO, T 500-2-500/4, (Ref.:M6193)

Format: 520 x 720 mm

Preis: auf Anfrage

Flachstapelanleger

2 Falzwerk - 4 Falztaschen: T500-2-500/4

Mobiles Schwert: T500-3-X

Auch mit einfacher Lieferung

Lärmabsorbierende Hauben

Schuppenauslage A 56 |

|

|

Heiber + Schröder, WP 1400 matic, 2003 (Ref.:M6483)

Baujahr: 2003 Format: 80 - 1400 mm

Preis: auf Anfrage

einbahniger Betrieb:

Länge A 100 mm - 1240 mm

Breite B 80 mm - 1400 mm

Länge Fenster/Futterstoff C 60 mm - 720 mm

Breite Fenster / Futterstoff D 30 mm - 1140 mm

zweibahniger Betrieb:

Länge A 100 mm - 1180 mm

Breite B 80 mm - 660 mm

Länge Fenster/Futterstoff C 60 mm - 720 mm

Breite Fenster / Futterstoff D 30 mm

Sonderprogramm für Abschnittlängen von 9

bis zu 30 Stück / die Minute |

|

|

KMK Printing & Packaging Machinery, KMK XY-B 530, 2024 (Ref.:M6309)

Baujahr: 2024 Format: 450 x 650 mm

Preis: auf Anfrage

Mittelgeschwindigkeits-Flexodruck Stanz-& Schlitzmaschine

der KMK XY-B-Serie

Max. Geschwindigkeit (Stück/Minute): 80

Laufgeschwindigkeit (Stück/Minute): 80

Max. Einzugsgröße (mm): 1600*2200/2400/2600/2800

Mindest. Futtergröße (mm): 450*650

Größe der Behälterzuführung (mm): 1800*2200/2400/2600/2800

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 - ± 1

Max. Druckgröße (mm): 1600*2000/2200/2400/2600

Dicke der Druckplatte (mm): 7,2

Axiale Einstellung der Druckwalze (mm):

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-B 480, 2024 (Ref.:M6308)

Baujahr: 2024 Format: 400 x 650 mm

Preis: auf Anfrage

Mittelgeschwindigkeits-Flexodruck Stanz-& Schlitzmaschine

der KMK XY-B-Serie

Max. Geschwindigkeit (Stück/Minute): 80

Laufgeschwindigkeit (Stück/Minute): 80

Max. Einzugsgröße (mm): 1400*2200/2400/2600/2800

Mindest. Futtergröße (mm): 400*650

Größe der Behälterzuführung (mm): 1600*2200/2400/2600/2800

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 - ± 1

Max. Druckgröße (mm): 1400*2000/2200/2400/2600

Dicke der Druckplatte (mm): 7,2

Axiale Einstellung der Druckwalze (mm):

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-B 400, 2024 (Ref.:M6307)

Baujahr: 2024 Format: 350 x 650 mm

Preis: auf Anfrage

Mittelgeschwindigkeits-Flexodruck Stanz-& Schlitzmaschine

der KMK XY-B-Serie

Max. Geschwindigkeit (Stück/Minute): 100

Laufgeschwindigkeit (Stück/Minute): 80

Max. Einzugsgröße (mm): 1200*2200/2400/2600/2800

Mindest. Futtergröße (mm): 350*650

Größe der Behälterzuführung (mm): 1400*2200/2400/2600/2800

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 - ± 1

Max. Druckgröße (mm): 1200*2000/2200/2400/2600

Dicke der Druckplatte (mm): 7,2

Axiale Einstellung der Druckwalze (mm):

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

|

|

|

|

KMK Printing & Packaging Machinery, KMK 1500-BMY, 2024 (Ref.:M6031)

Baujahr: 2024 Format: 1510 x 1100 mm

Preis: auf Anfrage

Stanzstil: Flachbettstanze

Max. Papiergröße: 1510 × 1100 mm

Min. Papiergröße: 550 × 550 mm

Max. Stanzgröße: 1500 × 1100 mm

Max. Stanzdruck: 350 T

Papierverarbeiteter Karton: 1-9 mm

Max. Stanzgeschwindigkeit: 4500 Blatt / h

Max. Stapelhöhe Anleger: 1400 mm

Max. Stapelhöhe Auslage: 1200 mm

Hauptmotorleistung: 11 kW

Gesamtleistung: 17 kW

Gewicht: 17,8 T

Abmessungen: 6300 x 4500 x 2500 mm

YouTube-Link: https://youtu.be/PaNQQakC |

|

|

KMK Printing & Packaging Machinery, KMK XY-HD 1-5 920, 2024 (Ref.:M6328)

Baujahr: 2024 Format: 900 x 2150 mm

Preis: auf Anfrage

KMK XY-HD 5+1 Hochauflösende Flexodrucker-Stanzmaschine

Max. Druckgröße: 900*2000

Max. Futtergröße: 900*2150

Größe des Skip-Feeds: 1100 x 2150

Mindest. Brettbreite: 270

Druckklischeestärke: 3,94–7,2 mm

Farbregister: ±0,5 mm

Ausrüstung:

Vorderkantenzuführungseinheit: 1

Druckereinheit (Keramikwalze + Gummiwalz

Druckereinheit (Keramikwalze + Rakel): 4

Trocknereinheit (IR): 1

Lackeinheit (IR): 1

Trocknereinheit: 1 |

|

|

KMK Printing & Packaging Machinery, KMK XY-HD 1-5 1224, 2024 (Ref.:M6329)

Baujahr: 2024 Format: 1200 x 2550 mm

Preis: auf Anfrage

KMK XY-HD 5+1 Hochauflösende Flexodrucker-Stanzmaschine

Max. Druckgröße: 1200*2400

Max. Futtergröße: 1200*2550

Größe des Skip-Feeds: 1400 x 2550

Mindest. Brettbreite: 350

Druckklischeestärke: 3,94–7,2 mm

Farbregister: ±0,5 mm

Ausrüstung:

Vorderkantenzuführungseinheit: 1

Druckereinheit (Keramikwalze + Gummiwalz

Druckereinheit (Keramikwalze + Rakel): 4

Trocknereinheit (IR): 1

Lackeinheit (IR): 1 |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 120-300, 2024 (Ref.:M6320)

Baujahr: 2024 Format: 270 x 600 mm

Preis: auf Anfrage

KMK XY-H 120 Serie Hochgeschwindigkeits-Flexodruck-Stanzmaschine mit Schlitzmaschine

Max. Geschwindigkeit (Stück/Minute): 150

Laufgeschwindigkeit (Stück/Minute): 120

Max. Einzugsgröße (mm): 900*2200/2400/2600/2800

Mindest. Futtergröße (mm): 270*600

Größe der Behälterzuführung (mm): 1100*2200/2400/2600/2800

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 - ± 1

Max. Druckgröße (mm): 900*2000/2200/2400/2600

Dicke der Druckplatte (mm): 7,2

Axiale Einstellung der Druckwalze (mm):

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 120-530, 2024 (Ref.:M6322)

Baujahr: 2024 Format: 450 x 650 mm

Preis: auf Anfrage

KMK XY-H 120 Serie Hochgeschwindigkeits-Flexodruck-Stanzmaschine mit Schlitzmaschine

Max. Geschwindigkeit (Stück/Minute): 120

Laufgeschwindigkeit (Stück/Minute): 120

Max. Einzugsgröße (mm): 1600*2200/2400/2600/2800

Mindest. Futtergröße (mm): 450*650

Größe der Behälterzuführung (mm): 1800*2200/2400/2600/2800

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 - ± 1

Max. Druckgröße (mm): 1600*2000/2200/2400/2600

Dicke der Druckplatte (mm): 7,2

Axiale Einstellung der Druckwalze (mm):

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 120-400, 2024 (Ref.:M6321)

Baujahr: 2024 Format: 350 x 650 mm

Preis: auf Anfrage

KMK XY-H 120 Serie Hochgeschwindigkeits-Flexodruck-Stanzmaschine mit Schlitzmaschine

Max. Geschwindigkeit (Stück/Minute): 150

Laufgeschwindigkeit (Stück/Minute): 120

Max. Einzugsgröße (mm): 1200*2200/2400/2600/2800

Mindest. Futtergröße (mm): 350*650

Größe der Behälterzuführung (mm): 1400*2200/2400/2600/2800

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 - ± 1

Max. Druckgröße (mm): 1200*2000/2200/2400/2600

Dicke der Druckplatte (mm): 7,2

Axiale Einstellung der Druckwalze (mm):

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 400, 2024 (Ref.:M6325)

Baujahr: 2024 Format: 350 x 650 mm

Preis: auf Anfrage

Hochgeschwindigkeits-Flexodruck-Stanzen mit

Schlitzmaschine (separate Führungskante)

Max. Geschwindigkeit (Stück/Minute): 200

Laufgeschwindigkeit (Stück/Minute): 0–200

Max. Futtergröße (mm): 1200*2200/2400/2600/2800

Mindest. Futtergröße (mm): 350*650

Größe der Behälterzuführung (mm): 1400*2200/2400/2600/2800

Max. Druckgröße (mm): 1200*2000/2200/2400/2600

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 mm - ± 0,75

Dicke der Druckplatte: 7,2 mm

Axiale Einstellung der Druckwalze: -± 5

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 480, 2024 (Ref.:M6326)

Baujahr: 2024 Format: 400 x 650 mm

Preis: auf Anfrage

Hochgeschwindigkeits-Flexodruck-Stanzen mit

Schlitzmaschine (separate Führungskante)

Max. Geschwindigkeit (Stück/Minute): 200

Laufgeschwindigkeit (Stück/Minute): 0–200

Max. Vorschubgröße (mm): 1400*2200/2400/2600/2800

Mindest. Futtergröße (mm): 400*650

Größe der Behälterzuführung (mm): 1600*2200/2400/2600/2800

Max. Druckgröße (mm): 1400*2000/2200/2400/2600

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 mm - ± 0,75

Dicke der Druckplatte: 7,2 mm

Axiale Einstellung der Druckwalze: -± 5

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 300, 2024 (Ref.:M6324)

Baujahr: 2024 Format: 270 x 600 mm

Preis: auf Anfrage

Hochgeschwindigkeits-Flexodruck-Stanzen mit

Schlitzmaschine (separate Führungskante)

Max. Geschwindigkeit (Stück/Minute): 250

Laufgeschwindigkeit (Stück/Minute): 0–200

Max. Futtergröße (mm): 900*2200/2400/2600/2800

Mindest. Futtergröße (mm): 270*600

Größe der Behälterzuführung (mm): 1100*2000/2400/2600/2800

Max. Druckgröße (mm): 900*2000/2200/2400/2600

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 mm - ± 0,75

Dicke der Druckplatte: 7,2 mm

Axiale Einstellung der Druckwalze: -± 5

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 530, 2024 (Ref.:M6327)

Baujahr: 2024 Format: 450 x 650 mm

Preis: auf Anfrage

Hochgeschwindigkeits-Flexodruck-Stanzen mit

Schlitzmaschine (separate Führungskante)

Max. Geschwindigkeit (Stück/Minute): 180

Laufgeschwindigkeit (Stück/Minute): 0-150

Max. Futtergröße (mm): 1600*2200/2400/2600/2800

Mindest. Futtergröße (mm): 450*650

Größe der Behälterzuführung (mm): 1800*2200/2400/2600/2800

Max. Druckgröße (mm): 1600*2000/2200/2400/2600

Dicke des Kartons (mm): 1,8–12

Farbregister (mm): ± 0,5 mm - ± 0,75

Dicke der Druckplatte: 7,2 mm

Axiale Einstellung der Druckwalze: -± 5

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen: |

|

|

KMK Printing & Packaging Machinery, KMK XY-H 150-2000, 2024 (Ref.:M6323)

Baujahr: 2024 Format: 450 x 170 mm

Preis: auf Anfrage

Hochgeschwindigkeits-Mini-Flexo-Slotter-Maschine der KMK XY-H-Serie

Max. Maschinengeschwindigkeit:

120 Blatt/Min

120 Stück/Min

Länge der Druckwalze: 1600 mm

Max. Futtergröße (L*B): 1700 x 600 mm

Mindest. Futtergröße (L*B): 450 x 170 mm

Mindest. Schlitzabstand: 80 x 80 mm

Mindest. Höhe der Box (H): 60 mm

Abmessung (Länge*Breite*Höhe): 3600 x 2100 x 1700 mm |

|

|

|

|

|

|

FKS, KB 2000, 2009 (Ref.:M6644)

Baujahr: 2009 Format: 320 × 310 mm Druckzahl: 13435 bindungen

Preis: auf Anfrage

Klebebinder mit einer Klammer,

Heißleimung,

manueller Umschlaganleger,

mit fahrbarem Untergestell,

Bindelänge: maxBand310 mm,

Buchdicke: maxBand60 mm,

Leistung: maxBand320 Bücher/h

Max Format: 320 × 310 mm

Gewicht: 186kg

230V-Stromversorgung |

|

|

CP Bourg, BB 3002, 2009 (Ref.:M6643)

Baujahr: 2009 Format: 385 x 750 mm

Preis: auf Anfrage

Klammern: 1

Rückenbeleimung: Hotmelt

Seitenbeleimung: Hotmelt

Frässtation: mit Absaugung

Frästiefe: einstellbar

Bogenformat:

- Maximal: 385 × 750 mm

- Minimal: 100 × 201 mm

Umschlagformat:

- Maximal: 385 × 750 mm

- Minimal: 100 × 201 mm

Buchdicke: |

|

|

Schneider, SF 80, 2004 (Ref.:M6571)

Baujahr: 2004 Format: 360 mm

Preis: auf Anfrage

Der SF-80 besticht insbesondere durch die grosse Vorstapelkapazität von rund 450 mm.

Die Kuverts werden stehend vorgestapelt und durch einen speziellen Saugkopf vereinzelt.

Der Transport erfolgt ohne Verformung des Materials.

Auslageband |

|

|

Sysform, 310 M, 2016 (Ref.:M6010)

Baujahr: 2016 Format: 310 mm

Preis: auf Anfrage

Schnittbreite: 310 mm

Schnitthöhe: 15 mm

Schmaler Schnitt: 40 mm

Schnitttiefe: 254 mm

Optische Lichtschnittlinie |

|

|

KMK Printing & Packaging Machinery, KMK XY-C 2800-400, 2024 (Ref.:M6312)

Baujahr: 2024 Format: 1200 x 2750 mm

Preis: auf Anfrage

KMK XY-C-Serie Rotationsstanze mit Kettenzuführung für Mehrfarbendruck Stanz-& Schlitzmaschine

Durchmesser: 400

Einzugsbereich (mm2): 1200*2750

Gültiger Druckbereich (mm2): 1200*2600

Arbeitsgeschwindigkeit (Stück/Minute): 0-60

Mindest. Futtergröße (mm): 350*650

Kartonstärke (mm): 2-12 |

|

|

KMK Printing & Packaging Machinery, KMK XY-C 2800-530, 2024 (Ref.:M6314)

Baujahr: 2024 Format: 1600 x 2750 mm

Preis: auf Anfrage

KMK XY-C-Serie Rotationsstanze mit Kettenzuführung für Mehrfarbendruck Stanz-& Schlitzmaschine

Durchmesser: 530

Einzugsbereich (mm2): 1600*2750

Gültiger Druckbereich (mm2): 1600*2600

Arbeitsgeschwindigkeit (Stück/Minute): 0-60

Mindest. Futtergröße (mm): 450*650

Kartonstärke (mm): 2-12 |

|

|

KMK Printing & Packaging Machinery, KMK XY-C 2800-480, 2024 (Ref.:M6313)

Baujahr: 2024 Format: 1400 x 2750 mm

Preis: auf Anfrage

KMK XY-C-Serie Rotationsstanze mit Kettenzuführung für Mehrfarbendruck Stanz-& Schlitzmaschine

Durchmesser: 480

Einzugsbereich (mm2): 1400*2750

Gültiger Druckbereich (mm2): 1400*2600

Arbeitsgeschwindigkeit (Stück/Minute): 0-60

Mindest. Futtergröße (mm): 400*650

Kartonstärke (mm): 2-12 |

|

|

KMK Printing & Packaging Machinery, KMK XY-C 2800-700, 2024 (Ref.:M6316)

Baujahr: 2024 Format: 2100 x 2750 mm

Preis: auf Anfrage

KMK XY-C-Serie Rotationsstanze mit Kettenzuführung für Mehrfarbendruck Stanz-& Schlitzmaschine

Durchmesser: 700

Einzugsbereich (mm2): 2100*2750

Gültiger Druckbereich (mm2): 2100*2600

Arbeitsgeschwindigkeit (Stück/Minute): 0-60

Mindest. Futtergröße (mm): 600*650

Kartonstärke (mm): 2-12 |

|

|

KMK Printing & Packaging Machinery, KMK XY-C 2800-600, 2024 (Ref.:M6315)

Baujahr: 2024 Format: 1800 x 2750 mm

Preis: auf Anfrage

KMK XY-C-Serie Rotationsstanze mit Kettenzuführung für Mehrfarbendruck Stanz-& Schlitzmaschine

Durchmesser: 600

Einzugsbereich (mm2): 1800*2750

Gültiger Druckbereich (mm2): 1800*2600

Arbeitsgeschwindigkeit (Stück/Minute): 0-60

Mindest. Futtergröße (mm): 500*650

Kartonstärke (mm): 2-12 |

|

|

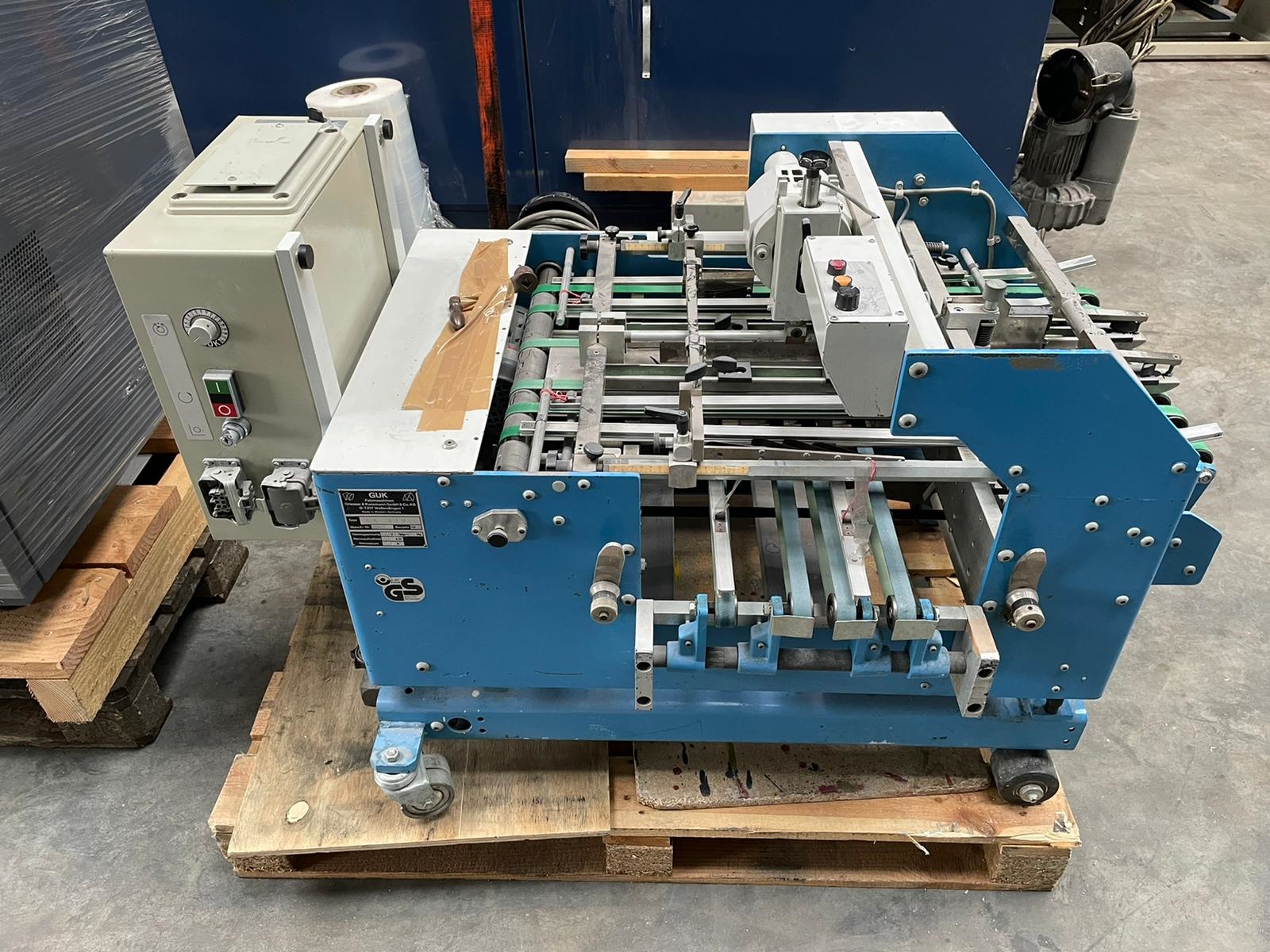

GUK, EK 420, 1989 (Ref.:M6064)

Baujahr: 1989 Format: 420 mm

Preis: auf Anfrage

- **Model**: GUK EK 420

- **Year of Manufacture**: 1989

- **Max. Sheet Size**: 420 mm

- **Folding Capacity**: Multi-fold capability for different paper formats

- **Condition**: Used, in stock

- **Applications**: Suitable for folding brochures, leaflets, and various paper materials

- **Location**: Western Europe

- **Operation**: High-volume production, flexible in handling multiple fold patterns and paper types

- **Size Category**: Medium-format folding machine |

|

|

MBO, T 500-3-X, (Ref.:M6194)

Format: 520 x 720 mm

Preis: auf Anfrage

- **Maximale Bogenbreite**: 530 mm (20 7/8 Zoll)

- **Maximale Bogenlänge**: 840 mm (33 1/8 Zoll)

- **Falzgeschwindigkeit**: Hochgeschwindigkeitsbetrieb

- **Falztaschen**: Bis zu 6 Falztaschen für vielseitige Falzmöglichkeiten

- **Messer-Einheit**: Pneumatisches Messer für präzises Kreuzfalzen |

|

|

|

|

|

|

|

|

|

|

KMK Printing & Packaging Machinery, KMK HBJ-D1200, 2024 (Ref.:M6041)

Baujahr: 2024

Preis: auf Anfrage

Produktionskapazität: 80-320 Stück / min

Geeignetes Material: 200-600 g / m2 Papierkarton, PE-beschichtetes Papier, Kraftpapier, Wellpappe

Länge: 100-450 mm, Grad: 5 ° - 40 °

Breite: 100-400 mm

Höhe: 15-200 mm

Gesamtleistung: 6,5 kW

Gesamtgewicht: 2,4T

Gesamtabmessung: 3600 x 1800 x 1700 mm

Stromquelle: 380V 50Hz |

|

|

KMK Printing & Packaging Machinery, KMK BJDB, 2024 (Ref.:M6042)

Baujahr: 2024

Preis: auf Anfrage

Produktionskapazität: 80-150 Stk / min

Geeignetes Material: 200-600 g / m2 Papierkarton, PE-beschichtetes Papier, Kraftpapier, Wellpappe

Länge: 100-450 mm, Grad: 4 ° - 50 °

Breite: 100-380 mm

Höhe: 15-200 mm

Gesamtleistung: 7 kW

Gesamtgewicht: 2,4T

Gesamtabmessung: 3600 x 1850 x 1800 mm

Stromquelle: 380V 50Hz |

|

|

|

|

Horizon, GM 5, (Ref.:M6448)

Format: 2 x 6 cm

Preis: auf Anfrage

1. **Funktion**: Trägt Leim oder Klebeband auf den Buchrücken von Buchblöcken oder gebundenen

Materialien auf.

2. **Größe**: Kann verschiedene Buchgrößen verarbeiten (abhängig von der Konfiguration, von klein

bis groß).

3. **Geschwindigkeit**: Hochgeschwindigkeitsbetrieb für effizientes und gleichmäßiges Verkleben.

4. **Kompatible Klebebandbreiten**: Unterstützt in der Regel Klebebandbreiten von 20 mm bis 60 mm.

5. **Automatisierung**: Automatisierte Einstellungen für schnelle Auftragswechsel,

Präzisionssensoren für die Klebebandausrichtung.

6. **Verarbeitung von Buchdicken**: Anpassbar für eine Vielzahl von Buchdicken.

7. **Benutzeroberfläche**: Touchscreen-Bedienfeld für einfache Bedienung.

8. **Produktionsumgebung**: Geeignet für

9. **Langlebigkeit**: Ausgelegt für den

10. **Wartung**: Leichter Zugang für Rei |

|

|

|

|

Horizon, StitchLiner 5500, 2007 (Ref.:M6467)

Baujahr: 2007 Format: 50 x 35 cm

Preis: auf Anfrage

This StitchLiner 5500 includes the following components

2x VAC-100a and VAC-100m Collating Towers

ST-40 Stacker

ACF-30 Accumulator and Folder

SPF-30 Saddle Stitcher

HTS-30 Three-Knife Trimmer

TB-30 Transport Belt

Key Features: - 20 stations - U-shaped layout: Efficient space utilization and easy monitoring -

Inline production from collating to finished product - Variable data processing: Handles

personalized p

printing - Fully automatic format ad

user-friendly operation, even for less e

Specifications: - Sheet sizes: Max.

Processing thickness: 8-200 pages (max.

booklets/ |

|

|

Brehmer, ST 250, 2000 (Ref.:M6507)

Baujahr: 2000 Format: 320 x 480 mm

Preis: auf Anfrage

Es handelt sich um eine komplette Linie aus folgenden Komponenten:

1. Brehmer UFA 250:

Typ: Unterschubfalzapparat

Funktionen:

- Automatisches Falzen von Papierbögen

- Anpassbare Falzarten für verschiedene Produktionsanforderungen

Besonderheiten:

- Hohe Präzision und Geschwindigkeit

- Benutzerfreundliche Bedienung

- Robuste Bauweise für den Dauerbetrieb |

|

|

Heidelberg, ST 450, 2006 (Ref.:M6600)

Baujahr: 2006 Format: 520 x 740 mm

Preis: auf Anfrage

6 x Stehendanleger

2 x Liegendanleger

2 x Umschlaganleger

Heftstation

Trimmer

Kreuzleger CHA. FJ.DKSA-0000058,Bj.2006 |

|

|

Polar, 115 ED, 2003 (Ref.:M6552)

Baujahr: 2003 Format: 1150 x 1150 mm

Preis: auf Anfrage

- Hersteller: Polar

- Modell: 115 ED

- Ident-Nummer: 7331088

- Baujahr: 2003

- Farbe: Silber

- Schneidbreite: 115 cm

- Zustand: Guter, gepflegter Zustand – direkt aus laufender Produktion

Ausstattung:

- Inklusive Rüttelautomat Polar RA-4

- Baujahr: 2003

- Seriennummer: 7382026

- Inklusive Papiersammelstation Polar TR

- Baujahr: 2002

- Seriennummer: 7293228 |

|

|

Polar, 137 EMC-MONITOR, 1989 (Ref.:M6478)

Baujahr: 1989 Format: 1370 x 1370 mm

Preis: auf Anfrage

- Modell: Polar 137 EMC Monitor

- Schnittbreite: 137 cm

- Max. Schneiddicke: 165 mm

- Einlegetiefe: 1450 mm

- Max. Presskraft: 6000 daN

- Minimale Schnittlänge: 30 mm mit Programmunterstützung

- Programmspeicher: bis zu 198 Programme

- Anzeige: Monitor für Schnittvorgaben und Programminformationen

- Antrieb: Hydraulisch

- Bedienung: Elektronische Steuerung mit Touchscreen

- Sicherheitsmerkmale: Zwei-Hand-Bedienu

- Gewicht: ca. 4500 kg

- Abmessungen: ca. 3200 x 1800 x 1800 mm

- Stromversorgung: 400V, 50Hz

- Zusätzliche Funktionen: Optische Schni |

|

|

|

|

Schneider, SENATOR S-Linie 115 H, 1997 (Ref.:M6608)

Baujahr: 1997 Format: 1150 x 1150 mm

Preis: auf Anfrage

Stacker “Knorr – 106-4-R“ (Mach. No.: 6560 016) - (Year of manufacture: 1995)

Vibrating table “Knorr – RLA-3“ (Mach. No.: 6559 027)

Good condition without any damage |

|

|

|

|

Perfecta, SEYPA 168 HTVC, 2007 (Ref.:M6611)

Baujahr: 2007 Format: 1680 x 1680 mm

Preis: auf Anfrage

Program with touch screen

Monitor Screen

Air table (stainless steel)

Air table

Side tables with air (stainless steel): Left & right

Safety cells

Stack Lift Type: Pallet feeder

Jogger Type: BASA 7 |

|

|

Polar, 137 ED-AT, 1996 (Ref.:M6632)

Baujahr: 1996 Format: 137 cm

Preis: auf Anfrage

- Hersteller: Polar

- Modell: 137 ED-AT

- Maschinentyp: Schneidemaschine

- Seriennummer: 6641326

- Schnittbreite: 137 cm

- Ausstattung:

• Vibrations-Tisch, Polar Typ RA-4, Baujahr 1999, SN 7082011

• Stapeleinleger, Polar Typ 145-4, Baujahr 1995, SN 6591161

• Schubladenschrank, 4 Auszüge, Metall

• Stehpult, 2-türig, mit Auszug

- Einsatzgebiet: Industrielle Druckereie |

|

|

Polar, 92 X, 2007 (Ref.:M6649)

Baujahr: 2007 Format: 920 x 920 mm

Preis: auf Anfrage

• Modell: Polar 92 X

• Typ: Schneidemaschine / Guillotine

• Baujahr: 2007

• Format: 920 × 920 mm

• Ausstattung: Digitales Programm, Fotozellen, Lufttisch rechts und links

• Zustand: Standard Maschine

• Geeignet für präzise Schneidarbeiten in der Weiterverarbeitung |

|

|

KMK Printing & Packaging Machinery, KMK XY-BFY 2000, 2024 (Ref.:M6310)

Baujahr: 2024 Format: 2000 mm

Preis: auf Anfrage

Papierbreite (mm): 2000

Max. Papiergeschwindigkeit (m/min): 141

Schlitzschnittzahl: 3-5

Mindest. Presslinienbreite (mm): 200

Mindest. Drucklinienbreite (mm): 200

Außendurchmesser der dünnen Klinge (mm): 260

Dicke der dünnen Klinge (mm): 1

Leistung (kW): 4

Gewicht (kg): 1200

Größe der Konfiguration (L*B*H): 2630*1791*1130 |

|

|

KMK Printing & Packaging Machinery, KMK XY-BFY 2500, 2024 (Ref.:M6311)

Baujahr: 2024 Format: 2500 mm

Preis: auf Anfrage

Papierbreite (mm): 2500

Max. Papiergeschwindigkeit (m/min): 141

Schlitzschnittzahl: 3-5

Mindest. Presslinienbreite (mm): 200

Mindest. Drucklinienbreite (mm): 200

Außendurchmesser der dünnen Klinge (mm): 260

Dicke der dünnen Klinge (mm): 1

Leistung (kW): 4

Gewicht (kg): 1300

Größe der Konfiguration (L*B*H): 3050*1791*1130 |

|

|

KMK Printing & Packaging Maschinery, KMK CM1100A, 2024 (Ref.:M6423)

Baujahr: 2024 Format: 450-1650mm

Preis: auf Anfrage

Papier-Schneidestärke

60-550G

(Die Dicke pro Papier muss >60G betragen,

Die Gesamtdicke des gesamten Papiers zusammen darf <550G sein)

Schneidlängenbereich

450-1650mm

Schneidgenauigkeit

Die Schneidlänge beträgt <1000 mm, Genauigkeit: +0,5 mm, Die Schneidlänge beträgt

>1000 mm, Genauigkeit: +%0,1

Schneideformat

1 Blatt |

|

|

MPS, EF330, 2004 (Ref.:M6270)

Baujahr: 2004 Format: 330 mm

Preis: auf Anfrage

8 x servoangetriebene Flexodruckstationen,

8 x UV-Trockner,

8 x wassergekühlte Kühlrollen,

2 x Rotationsstanzstationen,

Abfallaufwicklung,

Kantenschneideeinheit,

Zurückspulen,

BST-Kamerasystem.

Einschließen:

Magnetik: 80z, 96z, 100z, 104z, 108z, 116z, 124z

Druckwerkzeuge: 7 x 80z, 5 x 96z, 1 x 10

Anilox x 8 |

|

|

SPS Rehmus, Vitessa Star G2, 2001 (Ref.:M6532)

Baujahr: 2001 Format: 79 x 104 cm

Preis: auf Anfrage

• Fabrikat: SPS

• Typ: Vitessa Star G2

• Baujahr: 2001

• Maschinen-Nr.: 10001161

• Druckverfahren: Automatische Zylindersiebdruckmaschine mit Stoppzylinderprinzip

• Max. Bogenformat: ca. 790 x 1040 mm

• Min. Bogenformat: ca. 315 x 440 mm

• Materialstärke: 0,1 – 0,8 mm

• Druckgeschwindigkeit: bis zu 4.000 Bogen/Stunde

• Merkmale:

- Schneller Siebwechsel durch pneumati

- Zentrale 3-Punkt-Feineinstellung

- Robuste Maschinenbasis für industrie

// Anlagenkomponenten |

|

|

SPS Rehmus, Vitessa Star G2, 1997 (Ref.:M6635)

Baujahr: 1997 Format: 105x75cm

Preis: auf Anfrage

- Hersteller: SPS

- Modell: Vitessa Star G2

- Maschinentyp: Siebdruckmaschine

- Baujahr: 1997

- Ausstattung:

• Mabeg Einlegemaschine, Modell MS

• SPS Trocknungsanlage, Typ UV Top 1200, Baujahr 1993

• SPS Rehmus Erklärautomat, Typ Autostack S-02, Baujahr 1993

• Stahlplattform und Riffelblech auf Paletten

• Schaltschrank

• Siebdruckrahmen

- Einsatzgebiet: Industrieller Siebdruck |

|

|

SPS Rehmus, Vitessa Multistar G2/C, 2001 (Ref.:M6636)

Baujahr: 2001 Format: 70 x 102 cm

Preis: auf Anfrage

- Hersteller: SPS

- Modell: Vitessa Multistar G2/C

- Maschinentyp: Siebdruckmaschine (Komplettanlage)

- Baujahr: 2001

- Ausstattung:

• SPS Einlegemaschine

• SPS Trockner, Modell TS-M2, Baujahr 2001

• SPS Deklarationsautomat, Modell Autostack ASR 61+G2, Baujahr 2001

• Stahlplattform und Riffelblech auf Paletten

• Schaltschränke

- Einsatzgebiet: Industrieller Siebdruck |

|

|

|

|

|

|

|

|

NAGANO, CardExtra NAGEL, 2006 (Ref.:M6206)

Baujahr: 2006 Format: 32 x 65 cm

Preis: auf Anfrage

- **Maximale Papiergröße**: A3 (bis zu SRA3 Format)

- **Funktionalität**: Multifunktionale Endbearbeitung für Rillen und Schneiden

- **Anwendungen**: Ideal für Visitenkarten, Broschüren und andere Druckmaterialien

- **Effizienz**: Präzises Schneiden und Rillen für einen schnellen und genauen Arbeitsablauf |

|

|

KMK Printing & Packaging Machinery, KMK XY-AFG 2600, 2024 (Ref.:M6306)

Baujahr: 2024 Format: 420 x 2600 mm

Preis: auf Anfrage

Max. Papierformat (A+B) *2 (mm): 2600

Mindest. Papierformat (A+B) *2 (mm): 420

Max. Kartonlänge A (mm): 900

Mindest. Kartonlänge A (mm): 130

Max. Kartonbreite B (mm): 650

Mindest. Kartonbreite B (mm): 80

Max. Papierhöhe (C+D+C) (mm): 1200

Mindest. Papierhöhe (C+D+C) (mm): 170

Max. Kappengröße C (mm): 350

Mindest. Kappengröße C (mm): 50

Die Mindesthöhe D (mm): 100 |

|

|

KMK Printing & Packaging Machinery, KMK-1300, 2024 (Ref.:M6097)

Baujahr: 2024 Format: 1300 x 1100 mm

Preis: auf Anfrage

max. Bogenformat 1300 x 1100 mm

min. Bogenformat 350 x 350 mm

Präzision +- 1,5 mm

Geschwindigkeit 6.000 Bogen/ Std.

Energiebedarf 12 kW

Länge 12,5 m

Gewicht 6,8 t

Video in Produktion: https://www.youtube.com/watch?v=2Y4uEs7qX0E |

|

|

KMK Printing & Packaging Machinery, KMK-1300, 2017 (Ref.:M5585)

Baujahr: 2017 Format: 380 x 380 mm

Preis: auf Anfrage

Max. Format: 1100 x 1300 mm

Min. Format: 380 x 380 mm

Präzision: + - 1,0 mm

Geschwindigkeit: 6.000 Blatt / Stunde

Gesamtleistung: 11,5 kW

Abmessungen: 11 m × 1,95 m × 2,5 m

Gewicht: 6,8 t

https://www.youtube.com/watch?v=RAt-qWDbabQ |

|

|

JIGUO, MY-1320A, 2019 (Ref.:M6275)

Baujahr: 2019 Format: 450x400mm

Preis: auf Anfrage

Max. Papiergröße: 1320 x 960 mm

Mindest. Papiergröße: 450 x 400 mm

Max. Schnittgröße: 1300×940mm

Max. Druck: 340 Tonnen

Karton: 200-2000g/m2

Wellpappe: <8 mm (max. Dicke)

Max. Schnittgeschwindigkeit: 6000 Blatt/Stunde

Stanzgenauigkeit: ±0,15 mm

Mindest. Greiferkante: 8 mm

Max. Futterhaufenhöhe: 1650 mm

Max. Lieferstapelhöhe: 1500 mm

Gesamtleistung: 27 kW

Gewicht: 18 Tonnen

Luftbedarf: 0,8 MPa, >0,36 m³/min

Gesamtabmessungen: 7350×4530×2920mm |

|

|

KMK Printing & Packaging Machinery, KMK XY-V 1224, 2024 (Ref.:M6330)

Baujahr: 2024 Format: 1200 x 2550 mm

Preis: auf Anfrage

KMK XY-V Vollvakuumtransfer-Flexodrucker-Slotter-Stanzmaschine

Max. Druckgröße: 1200*2400

Max. Futtergröße: 1200*2550

Größe des Skip-Feeds: 1400 x 2550

Mindest. Brettbreite: 350

Druckklischeestärke: 3,94–7,2 mm

Farbregister: ±0,5 mm

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen:

Positiv: 150*150*150*150

Negativ: 300*60*300*60

Stanzen mit Schlitzaufsatz Typ:

280*60*280*60

180*180*180*180 |

|

|

KMK Printing & Packaging Machinery, KMK XY-V 1426, 2024 (Ref.:M6331)

Baujahr: 2024 Format: 1400 x 2750 mm

Preis: auf Anfrage

KMK XY-V Vollvakuumtransfer-Flexodrucker-Slotter-Stanzmaschine

Max. Druckgröße: 1400 * 2600

Max. Futtergröße: 1400*2750

Größe des Skip-Feeds: 1600 x 2750

Mindest. Brettbreite: 430

Druckklischeestärke: 3,94–7,2 mm

Farbregister: ±0,5 mm

Mindest. Schlitzabstand (mm):

Elektrisches Schlitzen: 300*100*300*100

Manuelles Schlitzen:

Positiv: 160*160*160*160

Negativ: 300*60*300*60

Stanzen mit Schlitzaufsatz Typ:

280*60*280*60

180*180*180*180 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rollenoffset |

MPS, EF 410-8, 2007 (Ref.:M6454)

Baujahr: 2007

Preis: auf Anfrage

Aus erster Hand

Einzelabrolleinheit S-1000

Antistatischer Stab

Einspeiseeinheit

Corona-Behandlung

Teknek Bahnreinigung

8x Flexodruckwerk

8x automatische Registerkontrolle |

|

|

MPS, EF 410-8 UV Flexo, 2007 (Ref.:M6460)

Baujahr: 2007

Preis: auf Anfrage

Erste Hand

Ausstattung:

- Einzelfach-Abwickeleinheit S-1000

- Antistatik-Stange

- Einzugseinheit

- Corona-Behandlung

- Teknek-Bahnenreinigung

- 8x Flexodruckeinheiten

- 8x Automatische Registersteuerung

- 8x Kühlwalze

- 8x GEW-UV-Trockner

- Schienensystem

- 1x Vertikale Doppelschnitt-Einheit

- 1x Automatische Registersteuerung für

- 1x BST Powerscope 3000 Videoinspektion |

|

|

|

|

Nilpeter, FA 3300, 2002 (Ref.:M6503)

Baujahr: 2002 Format: 320 mm

Preis: auf Anfrage

Technische Spezifikationen – UV Flexodruckmaschine

Allgemein:

- Anzahl der Druckwerke: 7

- Drucktechnologie: UV Flexo

- Trocknungssystem: UV GEW

- Kühlsystem: Luftgekühlte UV-Lampen

- UV-Lampen: 1 Stück

- Inspektionssystem: BST Kamera

- Oberflächenbehandlung: Corona-Vorbehandlung

- Lackiereinheit: Vorhanden

- Materialbreite: 157 – 333 mm

- Maximale Druckbreite: 320 mm

Stanzeinheit: |

|

|

|

Papierverarbeitung |

KMK Printing & Packaging Machinery, KMK ZLFM-1080MCW, 2025 (Ref.:M6220)

Baujahr: 2025

Preis: auf Anfrage

Basiseinstellung:

1. Automatische Zuführung: Blattzuführung, wellenlose Servomotorzuführung, 8 Saugdüsen

Erzielen Sie eine hohe Geschwindigkeit und hohe Präzision, um sicherzustellen, dass das Papier

kontinuierlich zugeführt wird

in die Maschine. Nonstop-Anleger, Standardkonfiguration mit Vorstapeleinheit.

Saugvorrichtung garantiert Stabilität und reibungslosen Papierversand.

2. Pulver entfernen Kalander: Heizwalze mit Schaber reinigen effektiv das Pulver

und Staub auf der Papieroberfläche. Verbessern Sie die Helligkeit nach dem Laminieren.

3. Leimbeschichtungseinheit auf Wasserbasis: Walzenbeschichtung, Beschichtung von Leim auf den

Blättern.

4. IR-Trockner: Mit Infrarotlampenheizun

Umlauftrocknungskanal.

5. Haupteinheit für die Laminierung: Meh

Folienkaschierung / Fensterfolienkaschie

Presszylinder der Laminierungsheizung: D |

|

|

KMK Printing & Packaging Machinery, KMK ZLFM-1080SJR, 2025 (Ref.:M6221)

Baujahr: 2025

Preis: auf Anfrage

Non-Stop-Anleger

Non-Stop-Stapler

Heißmesserschneider und Scheibenschneider

Formtemperaturregler

Anti-Curling aus dünnem Papier

Frontlage

Blätter zeichnen

Optional:

- Kettenmesser-Schneidsystem

- Doppellaminierung, Prägeeinheit

- UV-Verstärkungseinheit

- Puderreinigungsapparat

Youtube-Video Link: https://youtu.be/kKX |

|

|

KMK Printing & Packaging Machinery, KMK ZLFM-1080LCR, 2025 (Ref.:M6222)

Baujahr: 2025

Preis: auf Anfrage

max. Geschwindigkeit 100 m/min, 40-70 kWh

Mit neuester Laminiertechnologie

Jenseits der Folienbeschichtungstechnologie

1 bis 2 Personen zu bedienen

Basiseinstellung:

Automatischer Einzug: Blatteinzug, wellenloser Servomotoreinzug, 8 Saugdüsen erreichen eine hohe

Geschwindigkeit und hohe Präzision, um sicherzustellen, dass das Papier kontinuierlich in die

Maschine eingezogen wird. Nonstop-Anleger, Standardkonfiguration mit Vorstapeleinheit.

Saugvorrichtung garantiert Stabilität und reibungslosen Papierversand.

Puderentfernungskalander: Heizwalze mit

Papieroberfläche. Verbessern Sie die Hel

Laminierungs-Haupteinheit: Mehrzweck für

Filmlaminieren, Leimbeschichtungs- und T

ist mit einem separaten Umlauftemperatur |

|

|

|

|

KMK Printing & Packaging Machinery, KMK ZLFM-1080LC, 2025 (Ref.:M6293)

Baujahr: 2025

Preis: auf Anfrage

max. Geschwindigkeit 100 m/min, 40-70 kWh

Mit neuester Laminiertechnologie

Jenseits der Folienbeschichtungstechnologie

1 bis 2 Personen zu bedienen

Basiseinstellung:

Automatischer Einzug: Blatteinzug, wellenloser Servomotoreinzug, 8 Saugdüsen erreichen eine hohe

Geschwindigkeit und hohe Präzision, um sicherzustellen, dass das Papier kontinuierlich in die

Maschine eingezogen wird. Nonstop-Anleger, Standardkonfiguration mit Vorstapeleinheit.

Saugvorrichtung garantiert Stabilität und reibungslosen Papierversand.

Puderentfernungskalander: Heizwalze mit

Papieroberfläche. Verbessern Sie die Hel

Laminierungs-Haupteinheit: Mehrzweck für

Filmlaminieren, Leimbeschichtungs- und T

ist mit einem separaten Umlauftemperatur |

|

|

KMK Printing & Packaging Machinery, KMK ZLFM-1080MC, 2025 (Ref.:M6292)

Baujahr: 2025

Preis: auf Anfrage

Basiseinstellung:

1. Automatische Zuführung: Blattzuführung, wellenlose Servomotorzuführung, 8 Saugdüsen

Erzielen Sie eine hohe Geschwindigkeit und hohe Präzision, um sicherzustellen, dass das Papier

kontinuierlich zugeführt wird

in die Maschine. Nonstop-Anleger, Standardkonfiguration mit Vorstapeleinheit.

Saugvorrichtung garantiert Stabilität und reibungslosen Papierversand.

2. Pulver entfernen Kalander: Heizwalze mit Schaber reinigen effektiv das Pulver

und Staub auf der Papieroberfläche. Verbessern Sie die Helligkeit nach dem Laminieren.

3. Leimbeschichtungseinheit auf Wasserbasis: Walzenbeschichtung, Beschichtung von Leim auf den

Blättern.

4. IR-Trockner: Mit Infrarotlampenheizun

Umlauftrocknungskanal.

5. Haupteinheit für die Laminierung: Meh

Folienkaschierung / Fensterfolienkaschie

Presszylinder der Laminierungsheizung: D |

|

|

KMK Printing & Packaging Machinery, KMK RFM-106MC, 2024 (Ref.:M5588)

Baujahr: 2024 Format: 1060 × 1100mm

Preis: auf Anfrage

Max. Papiergröße: B1060×L1100mm

Mindest. Papiergröße: B320×L300mm

Max. mechanische Geschwindigkeit: 100 m/min, 11.000 Blatt/Stunde

Laminiergeschwindigkeit: 20-100 m/min

Papierstärke: 105-500 g/m²

Stapelhöhe: 1300 mm

Stapelhöhe des Staplers: 1300 mm

Gesamtleistung: 78 kW (380 V, AC3f, 50 Hz) (normaler Betrieb

Leistung: 28-38kW)

Gesamtabmessungen: L 11277 × B 2510 × H 3030 mm

https://www.youtube.com/watch?v=TPqhpGp3 |

|

|

KMK Printing & Packaging Machinery, KMK HT-760P, 2024 (Ref.:M5378)

Baujahr: 2024 Format: 760 x 520 mm

Preis: auf Anfrage

Max. Stanzformat: 760 x 520 mm

Min. Stanzformat: 320 x 260 mm

Max. Druck: 250 Tonnen

Dicke von Wellpappe: 80g/m bis E-Welle = 4mm

Stanzpräzision: ±0.075mm

Max. Anleger Palettenhöhe: 1280 mm

Maximale Stapelhöhe der Lieferung: 1160 mm

Max. Geschwindigkeit: 9.000 Bogen / Stunde

Max. Stanz- und Strippgeschwindigkeit: 9.000 Bogen / Stunde

Video link: https://youtu.be/DAAeRV-YKDY |

|

|

KMK Printing & Packaging Machinery, KMK XY-2600, 2024 (Ref.:M6299)

Baujahr: 2024 Format: 420 x 2600 mm

Preis: auf Anfrage

Technologische Parameter:

Klebebox:

Max. Papierformat (A+B) *2 (mm): 2600

Mindest. Papierformat (A+B) *2 (mm): 420

Max. Kartonlänge A (mm): 900

Mindest. Kartonlänge A (mm): 130

Max. Kartonbreite B (mm): 650

Mindest. Kartonbreite B (mm): 80

Max. Papierhöhe (C+D+C) (mm): 1200

Mindest. Papierhöhe (C+D+C) (mm): 170

Max. Kappengröße C (mm): 350

Mindest. Kappengröße C (mm): 50

Die Mindesthöhe D (mm): 100 |

|

|

|

|

KMK Printing & Packaging Machinery, KMK HT-1050A, 2024 (Ref.:M5379)

Baujahr: 2024 Format: 730 x 1040 mm

Preis: auf Anfrage

Max. Stanzformat: 730 x 1040 mm

Max. Druck: 300 Tonnen

Materialdicke: 0,1 - 2 mm

Stanzpräzision: ± 0,1 mm

Max. Anleger Palettenhöhe: 1280 mm

Max. Geschwindigkeit: 7.500 Bogen / Stunde

Maschinengewicht: 15.000 kg

Abmessungen: Länge 582 x Breite 386,5 x Höhe 260 cm

Strom: 16 kw

YouTube-Link: https://youtu.be/StMm3ywLfQ8 |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050, 2024 (Ref.:M6425)

Baujahr: 2024

Preis: auf Anfrage

Max. Schnittgröße: 730 x 1040 mm

Innenmaße der Stanze: 760 x 1144 mm

Schneidplattengröße: 736 x 1080 mm

Min. Greiferlänge: 8 mm

Schnittgenauigkeit: ±0,1 mm

Max. Schneiddruck: 350 t

Max. Schnittgeschwindigkeit: 7500 Bogen/Stunde

Vorstapelhöhe: 1550 mm

Stapelhöhe der Auslage: 1400 mm

Karton: 0,1-2 mm

Wellpappe: < 4 mm

Hauptmotorleistung: 11 kW

Heizflächenleistung: /

Gesamtleistung: 17,8 kW

Gewicht: 16 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050Q, 2025 (Ref.:M6426)

Baujahr: 2025

Preis: auf Anfrage

Max. Schnittgröße: 730 x 1040 mm

Innenmaße der Stanze: 760 x 1144 mm

Schneidplattengröße: 736 x 1080 mm

Min. Greiferlänge: 8 mm

Schnittgenauigkeit: ±0,1 mm

Max. Schneiddruck: 350 t

Max. Schnittgeschwindigkeit: 7500 Bogen/Stunde

Vorstapelhöhe: 1550 mm

Stapelhöhe der Auslage: 1400 mm

Karton: 0,1-2 mm

Wellpappe: < 4 mm

Hauptmotorleistung: 11 kW

Heizflächenleistung: /

Gesamtleistung: 17,8 kW

Gewicht: 18 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050QQ, 2024 (Ref.:M6427)

Baujahr: 2024

Preis: auf Anfrage

Max. Schnittgröße: 730 x 1040 mm

Innenmaße der Stanze: 760 x 1144 mm

Schneidplattengröße: 736 x 1080 mm

Min. Greiferlänge: 8 mm

Schnittgenauigkeit: ±0,1 mm

Max. Schneiddruck: 350 t

Max. Schnittgeschwindigkeit: 7500 Bogen/Stunde

Vorstapelhöhe: 1550 mm

Stapelhöhe der Auslage: 1400 mm

Karton: 0,1-2 mm

Wellpappe: < 4 mm

Hauptmotorleistung: 11 kW

Heizflächenleistung: /

Gesamtleistung: 17,8 kW

Gewicht: 18 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050M, 2024 (Ref.:M6428)

Baujahr: 2024

Preis: auf Anfrage

Max. Schnittgröße: 730 x 1040 mm

Innenmaße der Stanze: 760 x 1144 mm

Schneidplattengröße: 736 x 1080 mm

Min. Greiferlänge: 8 mm

Schnittgenauigkeit: ±0,1 mm

Max. Schneiddruck: 600 t

Max. Schnittgeschwindigkeit: 7500 Bogen/Stunde

Vorstapelhöhe: 1550 mm

Stapelhöhe der Auslage: 1400 mm

Karton: 0,1-2 mm

Wellpappe: < 4 mm

Hauptmotorleistung: 15 kW

Heizflächenleistung: 24 kW

Gesamtleistung: 50 kW

Gewicht: 22 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050MQ, 2024 (Ref.:M6429)

Baujahr: 2024

Preis: auf Anfrage

Max. Schnittgröße: 730 x 1040 mm

Innenmaße der Stanze: 760 x 1144 mm

Schneidplattengröße: 736 x 1080 mm

Min. Greiferlänge: 8 mm

Schnittgenauigkeit: ±0,1 mm

Max. Schneiddruck: 600 t

Max. Schnittgeschwindigkeit: 7500 Bogen/Stunde

Vorstapelhöhe: 1550 mm

Stapelhöhe der Auslage: 1400 mm

Karton: 0,1-2 mm

Wellpappe: < 4 mm

Hauptmotorleistung: 15 kW

Heizflächenleistung: 24 kW

Gesamtleistung: 50 kW

Gewicht: 24 t |

|

|

Chengyuan, Fast 1050, 2022 (Ref.:M6436)

Baujahr: 2022

Preis: auf Anfrage

Min. Papiergröße: 400 x 360 mm

Max. Stanzgröße: 1040 x 730 mm

Papierbereich: Karton 80-1200 g/m², Wellpappe = 4 mm

Greiferrand: 8 mm

Max. Stanzgeschwindigkeit: 7500 s/h

Max. Stanzdruck: 300T

Gesamtleistung 23 kW, Leistung 380 V 50 Hz, Gesamtgewicht: 16T

Abmessungen: 7016×4049×2030 mm

Videolink: https://www.youtube.com/watch?v=1W7EIdcv6_s |

|

|

Hang, 107-30, 1993 (Ref.:M6212)

Baujahr: 1993 Format: 3 x 8 mm

Preis: auf Anfrage

Anzahl Bohrköpfe: 4

Bohrerdurchmesser: 3-8 mm

Bohrabstand: 36-260 mm

Stapelhöhe: 60 mm

Drehzahl: 1800/min |

|

|

Hang, 106 DT, - (Ref.:M6556)

Preis: auf Anfrage

• Hersteller: Hang (Constantin Hang GmbH)

• Modell: DT 106 (auch bekannt als 106 DT)

• Maschinentyp: Papierbohrmaschine / Papierlochmaschine

• Bohrspindeln: 2 Stück, verstellbar

• Bohrdurchmesser: 3 – 20 mm (Standard bis 14 mm, optional mit Hohlschaft bis 20 mm)

• Tischgröße: ca. 110 × 68 cm (Breite × Tiefe)

• Max. Bohrabstand vom Papierrand: bis 470 mm (Stirnlochbohrung ca. 300 mm)

• Max. Stapelhöhe: ca. 70 mm

• Bedienung: Fußpedal (elektrisch)

• Anschluss: 380–400 V Drehstrom (3-phasig)

• Maschinengewicht: ca. 250 kg

• Zustand: Gebraucht, technisch überprüf |

|

|

|

|

Heidelberg, SBG, 1963 (Ref.:M6648)

Baujahr: 1963 Format: 560 x 770 mm

Preis: auf Anfrage

• Modell: Heidelberg SBG

• Typ: 1-colour letterpress (Buchdruck)

• Anwendung: Papierverarbeitung / Stanz- und Druckarbeiten

• Baujahr: 1963

• Format: 560 × 770 mm

• Zustand: Standard Maschine

• Besonderheiten: Robuste klassische Buchdruckmaschine, ideal für Stanz-, Prägedruck- und

Spezialanwendungen |

|

|

Heidelberg, KS, 1962 (Ref.:M6519)

Baujahr: 1962 Format: 360 x 520 mm

Preis: auf Anfrage

- Buchdruckmaschine

- Max. Bogenformat: ca. 340 x 480 mm

- Papierstärke: bis ca. 4 mm

- Geschwindigkeit: bis zu 4.000 Bogen/Stunde

- **Tiegeldruck mit Schwingarmanleger**

- Präzise Passergenauigkeit und starker Pressdruck

- Geeignet für: Nummerieren, Stanzen, Prägen, Perforieren und Rillen

- Einstellbarer Pressdruck |

|

|

|

|

|

|

|

|

Lintec, LPM 300 GT, 1997 (Ref.:M6522)

Baujahr: 1997 Format: 300 mm

Preis: auf Anfrage

- **Druckverfahren:** 6-Farben UV-Buchdruck

- **Maximale Materialbreite:** 300 mm

- **Maximale Druckbreite:** 280 mm

- **Maximale Drucklänge (Rapportlänge):** 280 x 240 mm

- **Maximale Geschwindigkeit:** 7.200 Drucke pro Stunde

- **UV-Trocknung:** 6 GEW UV-Trockner

- **Stanzen:** 1 rotative Stanzstation

- **Aufwickler:** Integriert mit Schlitzfunktion (5 Messer)

- **Abwickler:** Mit Endlagesensor

- **Zusätzliche Ausstattung:**

- Rotometrics Druckkontrolle an der St

- Metallbasierte Polymer-Klischees

- 11 magnetische Druckzylinder |

|

|

|

|

KMK Printing & Packaging Machinery, KMK CM-1500A (2 Reels), 2024 (Ref.:M6294)

Baujahr: 2024 Format: 450 x 1650 mm

Preis: auf Anfrage

Modell CM-1500

Schneideform des Papiers Das obere Messer schneidet rückwärts, während das untere Messer

fixiert ist.

Papiergewicht 60-550g

Maximaler Rollendurchmesser 1800mm

Maximale Rollenbreite 1500mm

Schneidelängenbereich 450-1600mm

Anzahl der geschnittenen Blätter 2 Stück

Schneidegenauigkeit Schneidelänge =1000mm: +/-0,5mm

Schneidelänge >1000mm: +/-%0,1

Maximale Schneidgeschwindigkeit 400 Schn

Maximale Schneidgeschwindigkeit 300 m/Mi

Maximale Höhe des Kartonstapels 1500mm

Luftdruckanforderungen 0.8Mpa

Netzanschluss 380V/220V×50Hz |

|

|

KMK Printing & Packaging Machinery, KMK CM-1500A (1 Reels), 2024 (Ref.:M6279)

Baujahr: 2024 Format: 450 x 1650 mm

Preis: auf Anfrage

Modell CM-1500

Schneideform des Papiers Das obere Messer schneidet rückwärts, während das untere Messer

fixiert ist.

Papiergewicht 60-550g

Maximaler Rollendurchmesser 1800mm

Maximale Rollenbreite 1500mm

Schneidelängenbereich 450-1600mm

Anzahl der geschnittenen Blätter 2 Stück

Schneidegenauigkeit Schneidelänge =1000mm: +/-0,5mm

Schneidelänge >1000mm: +/-%0,1

Maximale Schneidgeschwindigkeit 400 Schn

Maximale Schneidgeschwindigkeit 300 m/Mi

Maximale Höhe des Kartonstapels 1500mm

Luftdruckanforderungen 0.8Mpa

Netzanschluss 380V/220V×50Hz |

|

|

KMK Printing packaging Maschinery, KMK XY-1060P, 2024 (Ref.:M6300)

Baujahr: 2024 Format: 450 x 360 mm

Preis: auf Anfrage

KMK XY-1060 P Stanz & Ausbrechmaschine (Vakuumzufuhr)

Max. Stanzgeschwindigkeit (Bogen/Stunde): 7500

Stanzgenauigkeit (mm): + 0,1

Max. Stanzdruck (t): 250

Max. Papiergröße (mm): 1060*760

Mindest. Papiergröße (mm): 450*360

Mindest. Stanzgröße (mm): 1050*750

Papier verarbeitet

Karton: 80-2000 g/m2

Wellpappe (max. Dicke/mm): < 5

Gesamtleistung (kW): 18

Gewicht (t): 16

Abmessungen (L*B*H) (mm): 5950*2100*2300 |

|

|

KMK Printing packaging Maschinery, KMK XY-1300P, 2024 (Ref.:M6301)

Baujahr: 2024 Format: 550 x 450 mm

Preis: auf Anfrage

KMK XY-1300 P Stanz & Ausbrechmaschine (Vakuumzufuhr)

Max. Stanzgeschwindigkeit (Bogen/Stunde): 5000

Stanzgenauigkeit (mm): + 0,25

Max. Stanzdruck (t): 300

Max. Papiergröße (mm): 1320*950

Mindest. Papiergröße (mm): 550*450

Mindest. Stanzgröße (mm): 1310*940

Papier verarbeitet

Karton

Wellpappe (max. Dicke/mm): < 6

Gesamtleistung (kW): 18

Gewicht (t): 18

Abmessungen (L*B*H) (mm): 7300*2300*2400 |

|

|

KMK Printing packaging Maschinery, KMK XY-1500P, 2024 (Ref.:M6302)

Baujahr: 2024 Format: 550 x 450 mm

Preis: auf Anfrage

KMK XY-1500 P Stanz & Ausbrechmaschine (Vakuumzufuhr)

Max. Stanzgeschwindigkeit (Bogen/Stunde): 4500

Stanzgenauigkeit (mm): + 0,25

Max. Stanzdruck (t): 300

Max. Papiergröße (mm): 1500*1100

Mindest. Papiergröße (mm): 550*450

Mindest. Stanzgröße (mm): 1490*1090

Papier verarbeitet

Karton

Wellpappe (max. Dicke/mm): < 8

Gesamtleistung (kW): 22

Gewicht (t): 20

Abmessungen (L*B*H) (mm): 8400*2600*2500 |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050T, 2024 (Ref.:M6459)

Baujahr: 2024

Preis: auf Anfrage

Max. Papiergröße: 750 x 1050 mm

Min. Papiergröße: 360 x 400 mm

Max. Schnittgröße: 730 x 1040 mm

Innenmaße der Stanze: 760 x 1144 mm

Schneidplattengröße: 736 x 1080 mm

Max. Folienprägegröße: 720 x 1040 mm

Min. Greiferlänge: 8 mm

Schnittgenauigkeit: ±0,1 mm

Präzision der Folienprägung: ±0,125 mm

Max. Schneiddruck: 350 t

Max. Schnittgeschwindigkeit: 7500 Bogen/

Max. Folienprägegeschwindigkeit: 7500 Bo

Max. Folienrollendurchmesser: 200~250 mm

Breite der vertikalen Folienrolle: 50~10

Horizontale Folienrollenbreite: 50-760 m |

|

|

Bobst, Autoplaten SP 142, - (Ref.:M6591)

Format: 1420 x 1020

Preis: auf Anfrage

Hersteller: Bobst, Schweiz

Modell: SP 142

Maschinenart / Machine Category: Stanzmaschine / Die Cutting Machine

Maschinentyp / Machine Type: Autoplatine / Autoplaten

Baujahr: --- (nicht angegeben)

Maschinen-Nr.: 057400108

Technische Daten:

- Max. Bogenformat: 1420 x 1020 mm

- Min. Bogenformat: 700 x 500 mm

- Geschwindigkeit: bis zu 4.500 Bogen/Stunde (serienabhängig)

- Stromanschluss: 380 V, 50 Hz

Besonderheiten:

- Robuste Schweizer Konstruktion

- Mechanische Steuerung mit seitlichem B

- Stapelanleger und Auslage für kontinui |

|

|

|

|

|

|

|

|

|

|

|

Vollpappe Verarbeitung |

Jagenberg, Diana 90-1, 1984 (Ref.:M6237)

Baujahr: 1984 Format: 91.5 x 75 cm

Preis: auf Anfrage

Jagenberg Diana 90-1

Technical details

Size: 915 mm

Year: 1989

3 points gluing

Condition: very good

Description:

straight line |

|

|

|

Vorstufe |

Glunz & Jensen, Quartz III 85, 2012 (Ref.:M6515)

Baujahr: 2012 Format: 850 mm

Preis: auf Anfrage

Glunz & Jensen Quartz III 85 – Druckplatten-Entwicklungsautomat

- Stückzahl: 1

- Hersteller: Glunz & Jensen

- Typ: Quartz III 85

- Anwendung: Automatische Entwicklung von Druckplatten (CTP-Platten)

- Kompatibel mit Thermo-CTP-Platten

- Integrierter Druckplattenstapler

- Plattenbreite: bis zu 850 mm

- Entwicklungs-, Spül- und Gummierungseinheit integriert

- Robuste Bauweise für den Dauerbetrieb

- Einfache Bedienung und Wartung |

|

|

|

Wellpappe Verarbeitung |

EMproject89, BM MULTI 2400S, 2022 (Ref.:M6178)

Baujahr: 2022 Format: 2400 mm x unbegrenzte Länge

Preis: auf Anfrage

Kapazität: bis zu 1200 Kartons pro Stunde.

Maximale Boardgröße: 2400 mm x unbegrenzte Länge

1x Handhalterwerkzeug

4x Rillräder

1x Querschneidwerkzeug

1x Skalpellwerkzeug |

|

|

MKS Maschinen Handels GmbH

Lothforster Str. 46, D-41849 Wassenberg-Germany

|

|